Pump Example

In this part, transport of fluid through an inclined pipe using a pump is modeled. Using this model, you will learn how to instantiate a pump and understand the impact of pipe inclination on the pump's performance.

Model to determine the head vs. flow rate characteristics of the pump.

Drag-in Components

Create a new model and drag the following components from the Modelica standard library:

- FixedBoundary: Use two components and rename them to suctionPressure and ambient.

Define Pump Parameters

Select the pump that you want to model. A pump manufacturer usually provides a pump curve like the following:

Use a pump that has a nominal speed of 1480 RPM. You can get the following information from the pump curve:

Medium (This parameter cannot be left blank.) Select a fluid from the drop-down menu, e.g. “Extension of the StandardWater package.”

flowCharacteristic: Using this parameter, define the total head vs. flow rate curve. It takes a function as an argument. You can select a linear, quadratic or polynomial function. Use the "quadratic flow characteristic, including linear extrapolation". You can open the function (click on the edit button) and check the inputs:

It takes two lists (arrays) of volume flow rate and pump head.

For a nominal speed of 1480 RPM, you get the following values from the curve:

After converting from m3/h to m3/s, you get the following:

N_nominal:Set it to 1480 rev/min.

use_powerCharacteristic: Set it to true.

powerCharacteristic: Using this parameter, define the power consumption vs. flow rate curve. It takes a function as an argument. Use the quadratic power characteristic function. You can open the function (click on the edit button) and check the inputs:

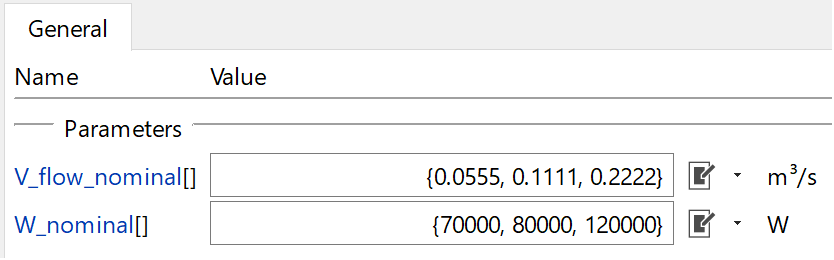

It takes two lists (arrays) of volume flow rate and power consumption.

For a nominal speed of 1480 RPM, you get the following values from the curve:

After converting from m3/h to m3/s and kW to W, you get the following:

Define Pipe Parameters

Medium (This parameter cannot be left blank.) Select a fluid from the drop-down menu, e.g. “Extension of the StandardWater package.”

Length: Total length of the pipe

isCircular: You can choose between circular and non-circular. If isCircular is set to false, then crossArea and perimeter parameters have to be defined. Note that it is assumed that the cross-sectional area is constant throughout the length.

Diameter: Diameter of the circular pipe

Roughness: Roughness of the inner pipe surface. This is a pipe material property, so common materials and their roughness values are listed below:

height_ab: If the pipe is inclined at an angle of 30 degrees, for example, height_ab will be length * sin (30 deg). Difference in height between the outlet (port_b) and inlet (port_a). Check the arrow direction of the pipe to determine inlet and outlet.

Define Ambient Parameters

nPorts: As the ambient is only connected to the pipe, set this value to 1.

Medium: Select a fluid from the drop-down menu, e.g. “Extension of the StandardWater package.”

Define Suction Pressure Parameters

nPorts: As the suctionPressure is only connected to the pump, set this value to 1.

Medium: Select a fluid from the drop-down menu, e.g. “Extension of the standard water package.”

Define Constant Speed Parameters

w_fixed: Define the fixed speed.

Initialize System Parameters

Go to the Initialization tab under system. Set m_flow_start as 1 kg/s. This would make the model numerically stable.

Connect and Simulate

Provide a simulation time in the Experiment Setup and simulate:

Analyze

Plot the pump head and volume flow rate. Pump head and volume flow rate can be obtained from the following variable: pump.head and pump.V_flow:

Compare the pump response for three different values of pipe.height_ab. Duplicate and rerun the experiment for 5, 10 and 15 m of height_ab:

As the pipe is tilted, more work (more head) has to be done by the pump, and it also leads to lower flow rate.