WOLFRAM SYSTEM MODELER

ApplicationExampleAn application example |

|

Wolfram Language

SystemModel["Modelica.StateGraph.UsersGuide.ApplicationExample"]

Information

This information is part of the Modelica Standard Library maintained by the Modelica Association.

In this section a more realistic, still simple, application example is given, to demonstrate various features of the StateGraph library. This example shows the control of a two tank system from the master thesis of Isolde Dressler (see literature).

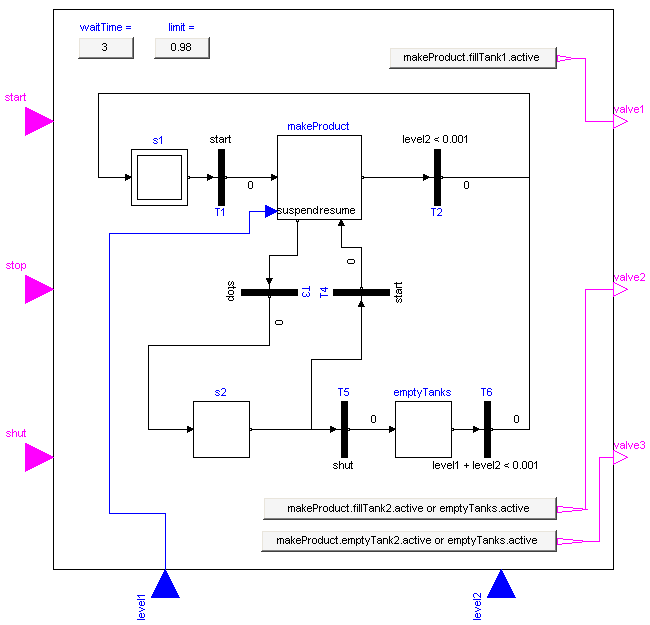

In the following figure the top level of the model is shown. This model is available as StateGraph.Examples.ControlledTanks.

In the right part of the figure, two tanks are shown. At the top part, a large fluid source is present from which fluid can be filled in tank1 when valve1 is open. Tank1 can be emptied via valve2 that is located in the bottom of tank2 and fills a second tank2 which in turn is emptied via valve3. The actual levels of the tanks are measured and are provided as signals level1 and level2 to the tankController.

The tankController is controlled by three buttons, start, stop and shut (for shutdown) that are mutually exclusive. This means that whenever one button is pressed (i.e., its state is true) then the other two buttons are not pressed (i.e., their states are false). When button start is pressed, the "normal" operation to fill and to empty the two tanks is processed:

- Valve 1 is opened and tank 1 is filled.

- When tank 1 reaches its fill level limit, valve 1 is closed.

- After a waiting time, valve 2 is opened and the fluid flows from tank 1 into tank 2.

- When tank 1 is empty, valve 2 is closed.

- After a waiting time, valve 3 is opened and the fluid flows out of tank 2.

- When tank 2 is empty, valve 3 is closed.

The above "normal" process can be influenced by the following buttons:

- Button start starts the above process. When this button is pressed after a "stop" or "shut" operation, the process operation continues.

- Button stop stops the above process by closing all valves. Then, the controller waits for further input (either "start" or "shut" operation).

- Button shut is used to shutdown the process, by emptying at once both tanks. When this is achieved, the process goes back to its start configuration. Clicking on "start", restarts the process.

The implementation of the tankController is shown in the next figure:

When the "start" button is pressed, the stateGraph is within the CompositeStep "makeProduct". During normal operation this CompositeStep is only left, once tank2 is empty. Afterwards, the CompositeStep is at once re-entered.

When the "stop" button is pressed, the "makeProduct" CompositeStep is at once terminated via the "suspend" port and the stateGraph waits in step "s2" for further commands. When the "start" button is pressed, the CompositeStep is re-entered via its resume port and the "normal" operation continues at the state where it was aborted by the suspend transition. If the "shut" button is pressed, the stateGraph waits in the "emptyTanks" step, until both tanks are empty and then waits at the initial step "s1" for further input.

The opening and closing of valves is not directly defined in the stateGraph. Instead via the "setValveX" components, the Boolean state of the valves are computed. For example, the output y of "setValve2" is computed as:

y = makeProduct.fillTank2.active or emptyTanks.active

i.e., valve2 is open, when step "makeProduct.fillTank2 or when step "emptyTanks" is active. Otherwise, valve2 is closed.