WOLFRAM SYSTEM MODELER

EngineThrottleControlClosed-loop throttle control synchronized to the crankshaft angle of an internal combustion engine |

|

Diagram

Wolfram Language

SystemModel["Modelica.Clocked.Examples.Systems.EngineThrottleControl"]

Information

This information is part of the Modelica Standard Library maintained by the Modelica Association.

This example shows how to model a non-periodic synchronous sampled data systems

with the Modelica.Clocked library. This is demonstrated at hand

of a closed-loop throttle control synchronized to the crankshaft angle of an

internal combustion engine. This system has the following properties:

- The engine speed is regulated with a throttle actuator.

- Controller execution is synchronized with the engine crankshaft angle.

- The influence of disturbances, such as a change in load torque, is reduced.

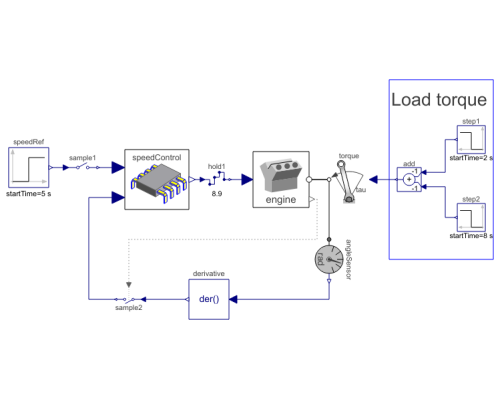

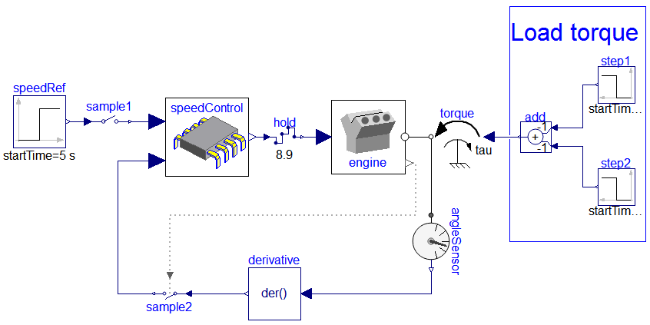

The complete system is shown in the figure below (diagram-layer):

Block speedControl is the discrete control system. The boundaries

of this controller are defined by sample1, sample2 and

hold. The sampling is done in terms of sensors within the engine

which observe its crankshaft angle; every 180° rotation of the crankshaft, the engine

internally synchronizes is throttles. The respective synchronization points are provided

as clocked outputs that in turn are used to trigger the external controller. The speed

controller therefore is automatically executed every half-rotation of the engine's

crankshaft in sync with the engine's internal throttle-cycle. The following diagram

illustrates the engine's respective internal setup:

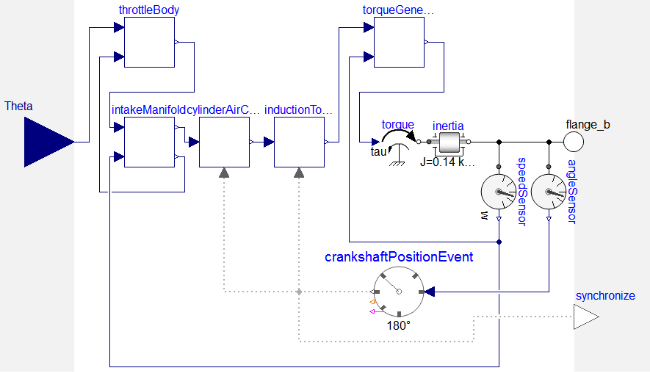

The crankshaftPositionEvent-clock is the event-clock synchronizing the

engine's internal throttle-cycle and external control. It produces a clock tick for

every half-rotation and is implemented as

RotationalClock.

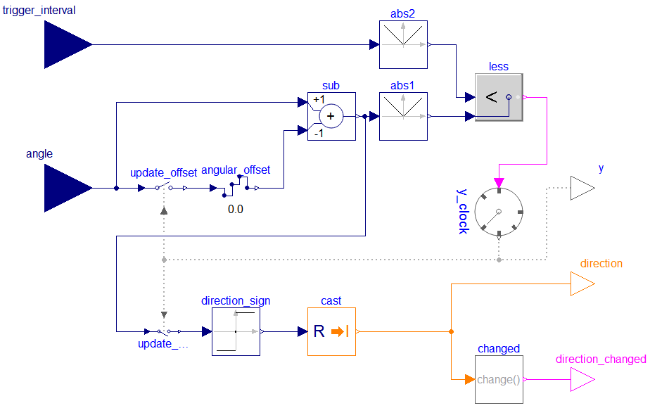

The following diagram illustrates the logic of such a rotational clock:

It accounts the angular of the last time a rotation has been

recognized (angular_offset). Given

angular_offset, the event-condition for rotations is:

abs(angle - angular_offset) >= abs(trigger_interval)

In our case, angle is the position of the crankshaft of the engine and

trigger_interval is 180°. In the end,

crankshaftPositionEvent samples it's own input angle to account

an offset used to decide when to tick; the clock's event condition depends on

the state present when the condition changed last time from being non-satisfied

to being satisfied, i.e., the state when the clock last ticked.

This example model is based on the following references:

- Crossley, P.R. and Cook, J. (1991):

- A nonlinear engine model for drivetrain system development.

International Conference on Control, Edinburgh, UK, March.

- Simulink® (R2010b) demo model

sldemo_enginewc.mdl: - Engine Timing Model with Closed Loop Control.

The

EngineThrottleControlexample uses the same parameter values as thesldemo_enginewc.mdldemo model which is shipped with the Simulink® software developed by The MathWorks, Inc. Hence, the simulation results of these models can be compared conveniently.

Components (12)

| speedRef |

Type: Step Description: Generate step signal of type Real |

|

|---|---|---|

| speedControl |

Type: SpeedControl Description: Discrete control of crankshaft speed by throttle actuation |

|

| sample1 |

Type: Sample Description: Sample the continuous-time, Real input signal and provide it as clocked output signal (clock is inferred) |

|

| hold1 |

Type: Hold Description: Hold the clocked, Real input signal and provide it as continuous-time output signal (zero order hold) |

|

| engine |

Type: Engine Description: Internal combustion engine. |

|

| step1 |

Type: Step Description: Generate step signal of type Real |

|

| step2 |

Type: Step Description: Generate step signal of type Real |

|

| add |

Type: Add Description: Output the sum of the two inputs |

|

| torque |

Type: Torque Description: Input signal acting as external torque on a flange |

|

| angleSensor |

Type: AngleSensor Description: Ideal sensor to measure the absolute flange angle |

|

| derivative |

Type: Der Description: Derivative of input (= analytic differentiations) |

|

| sample2 |

Type: SampleClocked Description: Sample the continuous-time, Real input signal and provide it as clocked output signal. The clock is provided as input signal |