Laser Beam Welding

| Introduction | Solve the PDE Model |

| Heat Transfer Model | Post-processing and Visualization |

| Domain | Nomenclature |

| Heat Source | References |

| Initial and Boundary Conditions |

Introduction

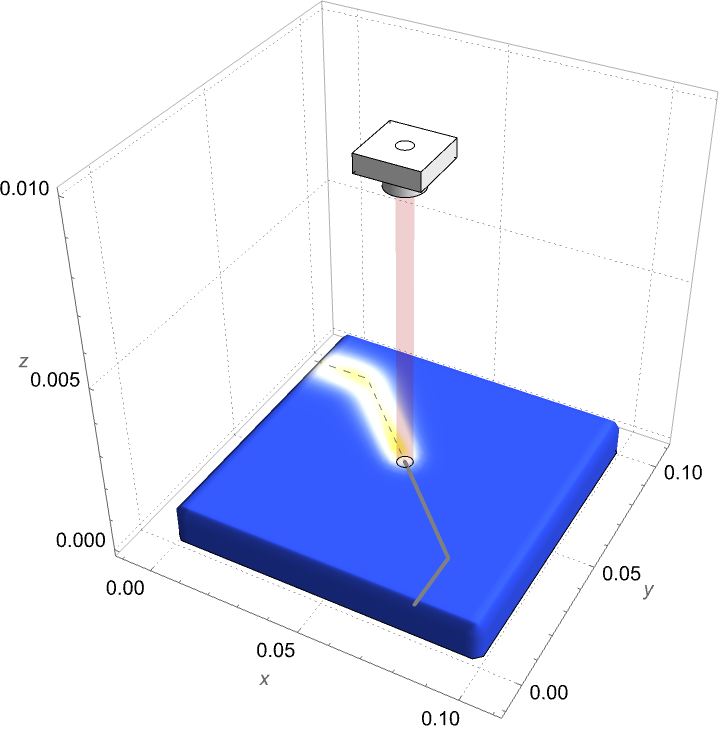

Laser beam welding (LBW) is a welding technique used to combine metals or thermoplastics. The laser beam provides concentrated, intense energy that heats up the materials at the welding location, and the parts melt together. In this example, two pieces of steel are to be welded together horizontally to form a larger plate. A laser beam follows the edges to be welded and traverses the steel pieces for the time period of ![]() . The model and material data are taken from [1, p. 114]:

. The model and material data are taken from [1, p. 114]:

The evolution of the temperature field during the welding process is simulated with a heat transfer model. For a successful welding, the maximum temperature ![]() at each time step must be above the melting point of the material used, in this case of steel at

at each time step must be above the melting point of the material used, in this case of steel at ![]() .

.

Once the object is welded after ![]() , heat continues to escapes through the object's surfaces by radiation to the surrounding area, and the plate will cool down toward the ambient temperature

, heat continues to escapes through the object's surfaces by radiation to the surrounding area, and the plate will cool down toward the ambient temperature ![]() .The cooling process can be inspected by calculating the time

.The cooling process can be inspected by calculating the time ![]() required to drop the plate temperature below a specific temperature

required to drop the plate temperature below a specific temperature ![]() .

.

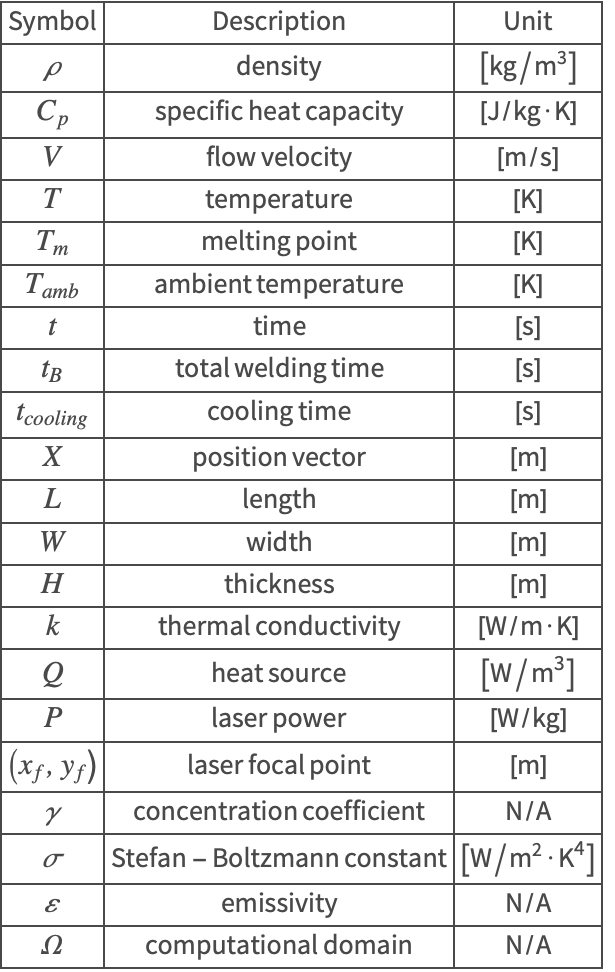

The symbols and corresponding units used here are summarized in the Nomenclature section.

Please refer to the information provided in "Heat Transfer" for a more general theoretical background for heat transfer analysis.

Heat Transfer Model

The heat equation (1) is used to solve for the temperature field in a heat transfer model:

When modeling the heat transfer in a solid medium, there is no internal fluid flow that could cause a heat convection. Therefore, the velocity term ![]() vanishes and the heat equation simplifies to:

vanishes and the heat equation simplifies to:

Since the internal convection introduced by the small amount of the melted steel is much weaker compared to the heat conduction, that effect will be neglected in this model:

Domain

Two steel pieces will be welded together to form a larger plate with a length of ![]() , a width of

, a width of ![]() and a thickness of

and a thickness of ![]() .

.

In order to get a good result, a grid finer than the default is used for the mesh generation. Here the max edge length is set to be ![]() , which means that there will be at least one hundred elements in the

, which means that there will be at least one hundred elements in the ![]() (length) and

(length) and ![]() (width) directions.

(width) directions.

Heat Source

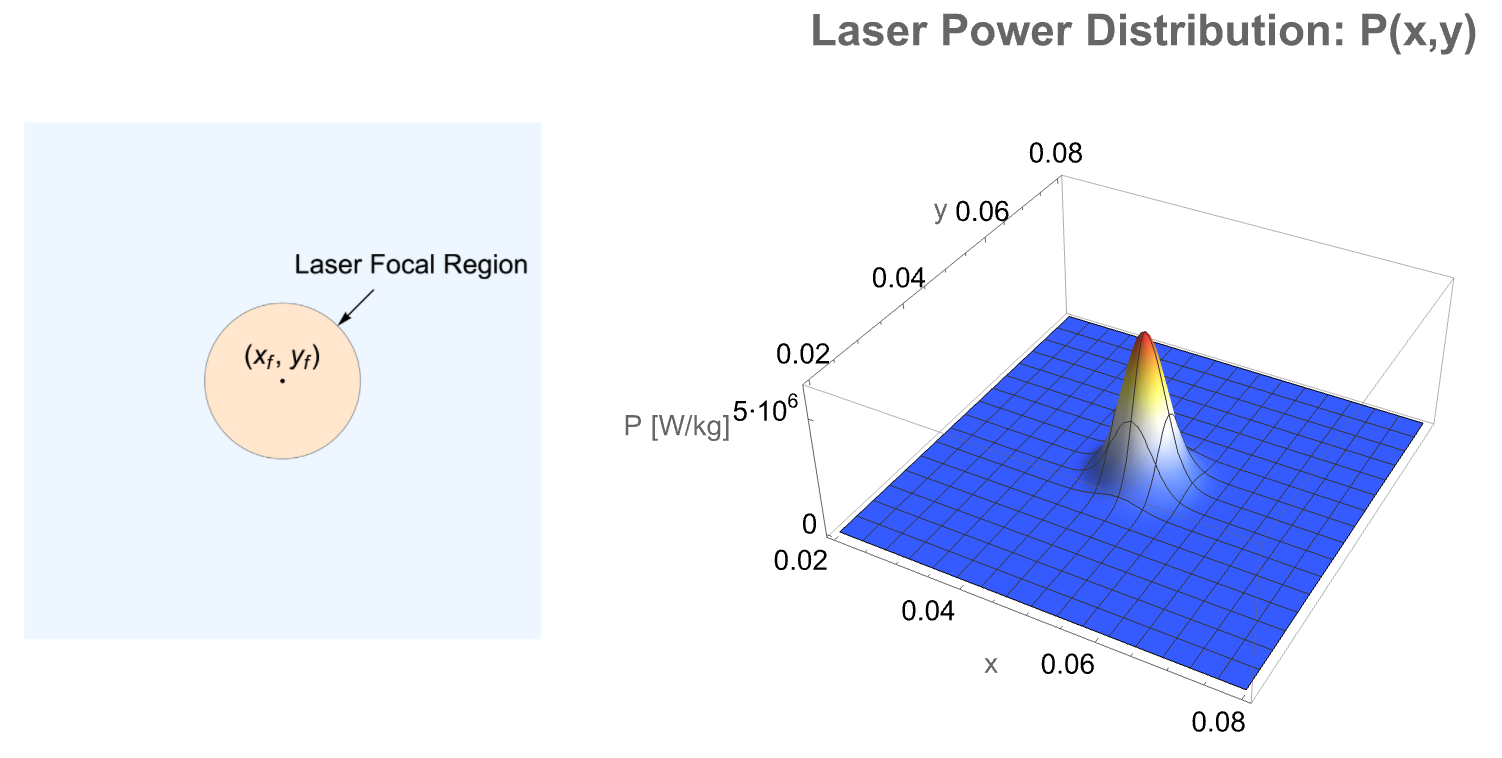

In this model, the laser beam provides the thermal energy to weld the steel pieces and is modeled by the heat source term ![]() in the heat equation (2). When applying the laser beam, all particles within the focal region are irradiated and heated up simultaneously.

in the heat equation (2). When applying the laser beam, all particles within the focal region are irradiated and heated up simultaneously.

Assume the distribution of the laser power ![]() is described by a Gaussian bell shape at a focus point

is described by a Gaussian bell shape at a focus point ![]() and is homogeneous in the

and is homogeneous in the ![]() (thickness) direction. A parameter

(thickness) direction. A parameter ![]() is introduced to control the degree of the laser concentration. A higher number implies a more concentrated beam:

is introduced to control the degree of the laser concentration. A higher number implies a more concentrated beam:

The laser beam is applied for a total time of ![]() . The path of the beam follows the edges to be welded and is described as a function of time

. The path of the beam follows the edges to be welded and is described as a function of time ![]() :

:

Note that all parameters except the independent variables are evaluated:

Initial and Boundary Conditions

At the beginning of the simulation, the temperature ![]() of the steel plate is assumed to be at the ambient temperature

of the steel plate is assumed to be at the ambient temperature ![]() .

.

All the object's surfaces are losing heat by radiation to the surrounding area. The Stefan–Boltzmann constant and the emissivity of steel are given by ![]() and

and ![]() , respectively.

, respectively.

Solve the PDE Model

Next the heat transfer PDE model is solved with NDSolve.

Post-processing and Visualization

To inspect the effect of the laser welding, the temperature distribution ![]() is visualized evolving in time.

is visualized evolving in time.

See this note about improving the visual quality of the animation.

Next, the maximum temperature ![]() is retrieved at each time step and compared with the melting point

is retrieved at each time step and compared with the melting point ![]() . Note that an effective welding requires

. Note that an effective welding requires ![]() during the welding process

during the welding process ![]() .

.

During the welding process: ![]() , the maximum temperature

, the maximum temperature ![]() is reached and exceeds the melting point

is reached and exceeds the melting point ![]() , which confirms the effectiveness of the laser welding. For

, which confirms the effectiveness of the laser welding. For ![]() , the joined steel plate gradually cools down by radiating to the surroundings and drops below the melting point at

, the joined steel plate gradually cools down by radiating to the surroundings and drops below the melting point at ![]() .

.

Nomenclature

References

1. Abali, B.E. Computational Reality: Solving Nonlinear and Coupled Problems in Continuum Mechanics. Advanced Structured Materials, vol 55. Springer, Singapore. (2017).