WOLFRAM SYSTEM MODELER

GearForceCalculationInnerClass calculating internal gear mesh contact forces |

|

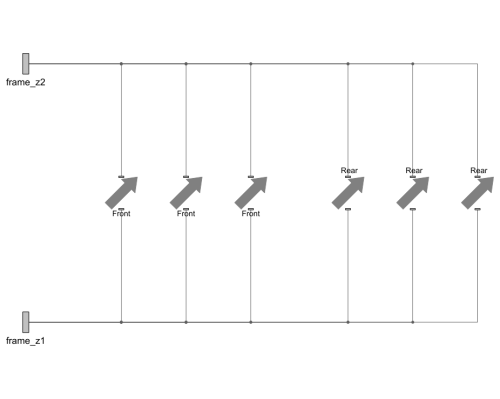

Diagram

Wolfram Language

SystemModel["RotatingMachinery.Gears.Components.GearForceCalculationInner"]

Information

Gear Forces Inner

This component contains six different ContactForcePointsInner components. That means that six spur gear forces are being calculated for six tooth pairs (maximum of three pairs can be in contact at a time) between the external gear connected to frame_z1 and the internal gear connected to frame_z2. The parameters that need to be specified in this component are the material and gear geometry.

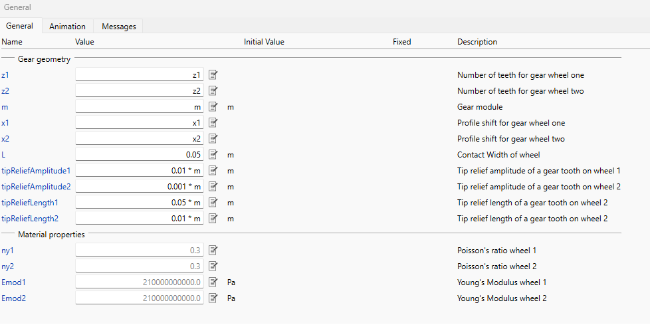

Figure 1: Gear contact parameter tab.

Tip relief, or tip modification, is necessary to avoid transients that occur when teeth come into contact. When two teeth come into contact, there is a deflection due to elastic deformation in the contact zone, which causes one tooth to take all the forces and increases the contact stress on that tooth.

Figure 2: Tip relief.

Figure 2 shows a tip relief implementation. Tip relief related parameters are set by two parameters for each gear,

The difference between the six forces are the parameters isFront and toothIndexShift.

If isFront is set to true, that means that the forward flank will be used, i.e. the flank that will be in contact when the wheel is rotating counterclockwise.

The parameter toothIndexShift is an index used at initialization to decide which tooth, in both gears, should be used in that tooth pair force calculation. This means that there are two zeros, two ones and two twos. Set isFront equal to true and false for the zeros and the ones. The settings will be:

| ContactForcePoint | isFront | toothIndexShift |

| Front0 | true | 0 |

| Front1 | true | 1 |

| Front2 | true | 2 |

| Rear0 | false | 0 |

| Rear1 | false | 1 |

| Rear2 | false | 2 |

Parameters (9)

| z1 |

Value: Type: Integer Description: Number of teeth for gear wheel one |

|---|---|

| z2 |

Value: Type: Integer Description: Number of teeth for gear wheel one |

| x1 |

Value: Type: Real Description: Profile shift for gear wheel one |

| x2 |

Value: Type: Real Description: Profile shift for gear wheel two |

| m |

Value: Type: Length (m) Description: Gear module |

| tipReliefAmplitude |

Value: 0.001 * m Type: Distance (m) Description: Tip relief amplitude of a gear tooth on the outer spur gear |

| tipReliefLength |

Value: 0.01 * m Type: Distance (m) Description: Tip relief length of a gear tooth on the outer spur gear |

| N_to_m |

Value: 200000 Type: Real (N/m) Description: Scale factor for animation of forces |

| useDebugPoints |

Value: false Type: Boolean |

Connectors (2)

Components (6)

| contactForcePointsInnerFront0 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

|

|---|---|---|

| contactForcePointsInnerFront1 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

|

| contactForcePointsInnerRear0 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

|

| contactForcePointsInnerRear1 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

|

| contactForcePointsInnerFront2 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

|

| contactForcePointsInnerRear2 |

Type: ContactForcePointsInner Description: Class for calculation of cylindrical contact force between two teeth on an outer and inner spur gear |

Used in Examples (2)

|

RotatingMachinery.Examples.Gears.SpurGears Application of a driven internal gearwheel |

|

|

RotatingMachinery.Examples.Gears.SpurGears Study of a driving internal gear |

Used in Components (1)

|

RotatingMachinery.Gears.PlanetaryGears Class containing a basic planetary gear model |