Hyperelasticity

Contents

Introduction

Materials like rubber or foam can be exposed to large deformations and still remain fully elastic. This means that if the load is removed, the deformation is fully reversible with no plastic deformation. These are called hyperelastic materials or Green elastic materials. Beyond rubber and foam, some biological tissue or polymers, which can have rubbery regimes, can fall into the hyperelastic material category. In contrast to hypoelastic materials, hyperelastic materials can be subjected to large deformations and rotations.

For small deformations, the difference in shape between the object before and after the deformation is small compared to the size of the object. In the case of large deformations, that is no longer the case, and the deformation needs to be accounted for. For example, a large deformation may have an effect on the shape of a surface a force is acting on. In the case of small deformations, this shape change is neglected because it is negligible.

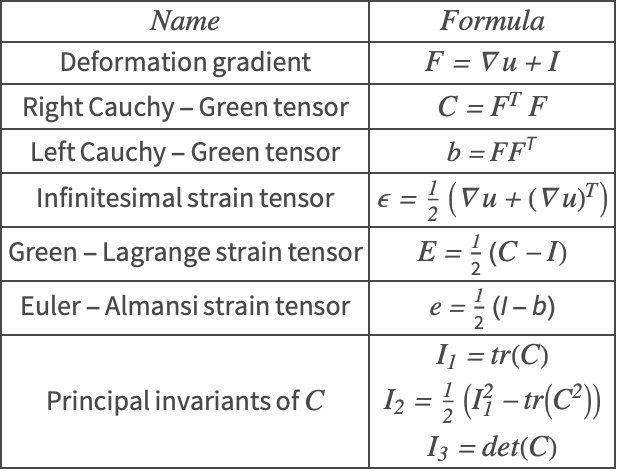

The mathematics behind large deformations is introduced in the section Deformation Gradient. Before proceeding, here is a summary of terms relevant in this section and their formulas:

Up until now, the only stress measure observed is the Cauchy stress ![]() . Cauchy stress is a stress measure defined in the spatial, deformed configuration, and ultimately, the Cauchy stress is the desired computational result. For hyperelastic material models, however, other stress measures are used. This is because typically, it is much harder to define the model setup in the deformed configuration; it is preferable to define the model setup in the undeformed, material configuration. Once the stress in the undeformed configuration has been computed, it is possible to obtain the Cauchy stress. This will be shown later. For now, the equilibrium equation relates a force density

. Cauchy stress is a stress measure defined in the spatial, deformed configuration, and ultimately, the Cauchy stress is the desired computational result. For hyperelastic material models, however, other stress measures are used. This is because typically, it is much harder to define the model setup in the deformed configuration; it is preferable to define the model setup in the undeformed, material configuration. Once the stress in the undeformed configuration has been computed, it is possible to obtain the Cauchy stress. This will be shown later. For now, the equilibrium equation relates a force density ![]()

![]() to the first Piola–Kirchhoff stress

to the first Piola–Kirchhoff stress ![]()

![]() . The equation of motion in the reference configuration is given as:

. The equation of motion in the reference configuration is given as:

Here ![]() and

and ![]() , are the body force density and the mass density, both in the undeformed configuration. In other words, where density means the quantity divided by the initial volume of material.

, are the body force density and the mass density, both in the undeformed configuration. In other words, where density means the quantity divided by the initial volume of material. ![]() is the unknown displacement vector.

is the unknown displacement vector. ![]() is the first Piola–Kirchhoff stress measured in [

is the first Piola–Kirchhoff stress measured in [![]() ] and is also defined in the undeformed configuration, so it is a force per undeformed area

] and is also defined in the undeformed configuration, so it is a force per undeformed area ![]() . The first Piola–Kirchhoff stress is often abbreviated with PK1.

. The first Piola–Kirchhoff stress is often abbreviated with PK1.

So far, the first Piola–Kirchhoff stress has been used for the equilibrium equation to express the setup in the initial configuration, and the Cauchy stress is available for finding the stresses in the deformed, final configuration. Unfortunately, there is more to it than that. The Cauchy stress is the current force per current area ![]() .

.

The general procedure for establishing a hyperelastic material model is to start from a scalar strain energy density function ![]() . The strain energy density function

. The strain energy density function ![]() is constructed from experiments and defines a given material. It is a measure of the energy stored in the material due to a deformation. This energy density function per unit undeformed volume is formulated as a function of a strain measure. The energy density function is then differentiated with respect to that strain measure and results in a stress measure.

is constructed from experiments and defines a given material. It is a measure of the energy stored in the material due to a deformation. This energy density function per unit undeformed volume is formulated as a function of a strain measure. The energy density function is then differentiated with respect to that strain measure and results in a stress measure.

Materials are considered elastic if their constitutive behavior can be expressed as a function of the current state of deformation only. When this condition holds, the stress measure of a particle at position ![]() is a function of the current deformation gradient

is a function of the current deformation gradient ![]() . The deformation gradient

. The deformation gradient ![]() is conjugate to the first Piola–Kirchhoff stress

is conjugate to the first Piola–Kirchhoff stress ![]() and it can be written:

and it can be written:

The double contraction ![]() of a stress tensor

of a stress tensor ![]() with the associated rate of deformation tensor

with the associated rate of deformation tensor ![]() describes the rate of internal mechanical work per unit reference volume. A strain energy density function is then given by [17, c. 5.2, p. 142]:

describes the rate of internal mechanical work per unit reference volume. A strain energy density function is then given by [17, c. 5.2, p. 142]:

Constitutive equations must describe relationships between compatible stress and strain measures [5, p. 498]. The first Piola–Kirchhoff stress ![]() and the deformation gradient

and the deformation gradient ![]() are such a compatible stress-strain pair. A strain energy density function can be expressed in equivalent forms in terms of different strain measures.

are such a compatible stress-strain pair. A strain energy density function can be expressed in equivalent forms in terms of different strain measures.

Constitutive behavior of solids is often given in terms of the material coordinates; the Lagrangian description is often preferred in solid mechanics [16, p. 61]. Since in solid mechanics setups, some aspects of the current configuration are generally not easily known, it is not convenient to work with stress tensors expressed in terms of the spatial configuration. In most cases, it is easier to work with stress tensors that are expressed in the reference configuration or an intermediate configuration [16, p. 109, p. 146]. To express the energy density function not only with the PK1 and the deformation gradient ![]() but also with the right Cauchy–Green deformation tensor

but also with the right Cauchy–Green deformation tensor ![]() , a new pseudo stress measure

, a new pseudo stress measure ![]() is introduced.

is introduced. ![]() is the second Piola–Kirchhoff stress measured in [

is the second Piola–Kirchhoff stress measured in [![]() ]. The second Piola–Kirchhoff stress is often abbreviated with PK2. The term pseudo stress means that this stress is defined neither in the undeformed nor in the deformed configuration.

]. The second Piola–Kirchhoff stress is often abbreviated with PK2. The term pseudo stress means that this stress is defined neither in the undeformed nor in the deformed configuration.

Like the stress field ![]() is said to be work conjugate to the strain field

is said to be work conjugate to the strain field ![]() , the stress field

, the stress field ![]() is said to be work conjugate to the strain field

is said to be work conjugate to the strain field ![]() [16, p. 155ff]. In other words, the Green–Lagrange strain

[16, p. 155ff]. In other words, the Green–Lagrange strain ![]() is compatible with the second Piola–Kirchhoff stress

is compatible with the second Piola–Kirchhoff stress ![]() [17, c. 5.2, p. 143]:

[17, c. 5.2, p. 143]:

Several other stress and work conjugates strains exist but will not be explored here.

As explained above, a strain energy density function can be expressed in equivalent forms in terms of different strain measures. For example, the energy density function ![]() is expressed in term of the Green–Lagrange strain

is expressed in term of the Green–Lagrange strain ![]() . Other possibilities for expressing an energy density function are to use, for example, the Cauchy tensors

. Other possibilities for expressing an energy density function are to use, for example, the Cauchy tensors ![]() , the infinitesimal strain

, the infinitesimal strain ![]() or invariants of

or invariants of ![]() . Depending on how the energy density function is expressed, for example,

. Depending on how the energy density function is expressed, for example, ![]() , the energy function is then differentiated with respect to that independent variable, for example,

, the energy function is then differentiated with respect to that independent variable, for example, ![]() .

.

If the strain energy density function is expressed in terms of the deformation gradient ![]() and the derivative of the strain energy density function is taken with respect to the deformation gradient

and the derivative of the strain energy density function is taken with respect to the deformation gradient ![]() , it leads to the PK1 stress:

, it leads to the PK1 stress:

since the deformation gradient ![]() is compatible with the first Piola–Kirchhoff stress

is compatible with the first Piola–Kirchhoff stress ![]() .

.

Differentiating a strain energy density ![]() that is a function of the Green–Lagrange strain

that is a function of the Green–Lagrange strain ![]() , the Cauchy deformation tensor

, the Cauchy deformation tensor ![]() or the infinitesimal strain

or the infinitesimal strain ![]() with respect to the strain measure will result in a second Piola–Kirchhoff stress

with respect to the strain measure will result in a second Piola–Kirchhoff stress ![]()

since the strain measures ![]() ,

, ![]() and

and ![]() are compatible with the second Piola–Kirchhoff stress

are compatible with the second Piola–Kirchhoff stress ![]() .

.

If the energy density function is expressed in a form that is compatible with a second Piola–Kirchhoff stress ![]() , it needs to be converted to a first Piola–Kirchhoff stress

, it needs to be converted to a first Piola–Kirchhoff stress ![]() such that it can be used in the equilibrium equation:

such that it can be used in the equilibrium equation:

A resulting second Piola–Kirchhoff stress ![]() can be converted to a first Piola–kirchhoff stress

can be converted to a first Piola–kirchhoff stress ![]() with the relation:

with the relation:

The equilibrium equation is then:

Nanson's formulas describe how stresses can be converted into each other and are summarized in the following list [5, p. 482]:

What complicates matters further with regard to reading literature is that some authors define the stress differently, in that they use a transposed version [11, ch2.2.3 p. 44]. It is possible to use, for example, ![]() , where the second subscript

, where the second subscript ![]() corresponds to the surface normal vector.

corresponds to the surface normal vector.

The transformation of quantities between the material and spatial configurations is called push-forward and pull-back operations [16, p. 82].

- The first Piola–Kirchhoff stress is used for the equilibrium equation, because entities need to be expressed in the initial configuration.

- The second Piola–Kirchhoff stress is commonly used for the constitutive equation, because the PK2 is compatible with the Green–Lagrange strain

and the right Cauchy tensor

and the right Cauchy tensor  .

.

As a side note, in the case of an infinitesimal strain measure ![]() , the stress measures

, the stress measures ![]() ,

, ![]() and

and ![]() are roughly the same, such that

are roughly the same, such that ![]() , and in that sense, the infinitesimal strain

, and in that sense, the infinitesimal strain ![]() is also compatible with the PK2

is also compatible with the PK2 ![]() .

.

St. Venant–Kirchhoff Model

The St. Venant–Kirchhoff model is a simple model of a hypoelastic material. The St. Venant–Kirchhoff model is a phenomenological model. This means it describes observed behavior. Its purpose is mainly educational, as it has deficiencies in the large deformation regime. In that case, the St. Venant–Kirchhoff model softens under compression that is not physical. In this case, the St. Venant–Kirchhoff model is used as an example to introduce formulating custom constitutive equations.

The simplest constitutive model is linear elasticity. Defined in terms of the strain, energy density is given as [14, p 13]:

where ![]() is the infinitesimal strain tensor,

is the infinitesimal strain tensor, ![]() is the first Lamé constant and

is the first Lamé constant and ![]() is the second constant, also known as shear modulus

is the second constant, also known as shear modulus ![]() . The Lamé constants can be related to the Young modulus and Poisson ratio, as shown in the section on Alternative Material Parameters.

. The Lamé constants can be related to the Young modulus and Poisson ratio, as shown in the section on Alternative Material Parameters. ![]() is the corresponding energy density function for linear elasticity.

is the corresponding energy density function for linear elasticity.

The St.Venant–Kichhoff model uses the above energy density function but uses the Green–Lagrange strain ![]() in place of the infinitesimal strain tensor

in place of the infinitesimal strain tensor ![]() .

.

For the Green–Lagrange strain ![]() , the energy density function

, the energy density function ![]() is given as [14, p 15]:

is given as [14, p 15]:

The derivative of the energy density function ![]() with respect to the Green–Lagrange strain

with respect to the Green–Lagrange strain ![]() is:

is:

where ![]() is the second Piola–Kirchhoff stress and

is the second Piola–Kirchhoff stress and ![]() is the identity matrix.

is the identity matrix.

Hyperelastic material laws are highly nonlinear, which can make them very challenging to solve. Depending on the amount of the final deformation, it is unrealistic to expect any solver to find a solution with the standard approach of iteratively solving a set of linearized equations. This is not a problem of the Wolfram Language specifically, but a challenge any PDE solving functionality faces. To work with this challenge, two main workflows are available. In both approaches, the force acting on the object is slowly increased. The two approaches are

The first approach is to create a parametric function with a parameter ![]() that has an influence on the amount of deformation. Initially, this parameter

that has an influence on the amount of deformation. Initially, this parameter ![]() may be set to 0, and a solution to the system of equations is obtained. This solution is then used as an initial seed for the next evaluation of the parametric system, where

may be set to 0, and a solution to the system of equations is obtained. This solution is then used as an initial seed for the next evaluation of the parametric system, where ![]() is slightly increased. That solution is then reused in the same manner until the parameter

is slightly increased. That solution is then reused in the same manner until the parameter ![]() reaches 1, which is equivalent to the full displacement of the system. This procedure was already made use of in the section about Hypoelastic Models.

reaches 1, which is equivalent to the full displacement of the system. This procedure was already made use of in the section about Hypoelastic Models.

The second approach uses time integration to achieve the same thing: slowly increase the amount of force acting on the object. The main advantage of using time integration is that NDSolve has an adaptive time step mechanism that choses the next time step automatically. In the parametric force increment approach, one has to choose the size of a next step manually, which is not the case for the pseudo time integration method. Here the system of equations is integrated from 0 to 1, which is an arbitrarily chosen end time. Time variable ![]() now takes the place of the parameter

now takes the place of the parameter ![]() and is used to slowly increase the force acting on the object. This approach will be shown in the section discussing the neo-Hookean material model. The following examples shows the parametric force increment approach.

and is used to slowly increase the force acting on the object. This approach will be shown in the section discussing the neo-Hookean material model. The following examples shows the parametric force increment approach.

As an example, a unit cube is used. The cube is under tension in the positive ![]() direction while at the same time fixed at

direction while at the same time fixed at ![]() .

.

In the following, the previous solution is used to start the nonlinear solve for the current solution.

Should the nonlinear solver not converge, the first thing to try is to increase nsteps, the number of steps taken. That the solver does not converge can have many causes. Even increasing the number of elements can make a solver fail to find a solution that it did find with fewer elements. In that case, one option is to use a coarse mesh, find a solution and use that as an initial seed for a fine grid computation. This approach is shown in the finite element best practice Solving Memory-Intensive PDEs. The example there uses an iterative solver, but the default linear solve can be used by removing the option that specifies the iterative solver.

For hyperelastic material models, one often wants to see the deformation to scale, since the deformations are large and visible. For this, the "ScalingFactor" of the deformation or the original geometry can be set to 1.

The following visualization is to scale.

The volume is smaller than the initial volume. More on this topic can be found in the section on Compressibility.

Computing the Cauchy stress from the strain works a little bit differently than in the linear elastic case. In the linear elastic case, it is possible to use the strain to recover the stress. Now, since the constitutive equations work with the second Piola–Kirchhoff stress, the deformation gradient ![]() is also needed to convert it to a Cauchy stress.

is also needed to convert it to a Cauchy stress.

If the stress you are interested in is the same as the stress the constitutive equation uses, which is the case for linear elastic material, then and only then, no displacement needs to be given.

Note that the first Piola–Kirchhoff stress is not symmetric and cannot be used, for example, in visualizing a von Mises stress, since that requires that the tensor used be symmetric.

Visualizing the von Mises stress over the deformed object is desired.

Next, the objective is to see if linear elasticity can be reproduced using the St. Venant–Kirchhoff model. For the infinitesimal strain ![]() , the energy density function

, the energy density function ![]() is given as [14, p 13]:

is given as [14, p 13]:

![]() is the first Lamé constant and

is the first Lamé constant and ![]() is the second constant, also known as shear modulus

is the second constant, also known as shear modulus ![]() . The Lamé constants can be related to the Young modulus and Poisson ratio.

. The Lamé constants can be related to the Young modulus and Poisson ratio.

The derivative of the energy density function ![]() with respect to the infinitesimal strain

with respect to the infinitesimal strain ![]() is:

is:

Next, the same model setup is computed using the linear elastic functionality. To make stresses better comparable, the typical engineering strain used for linear elastic materials is not used. It is possible to switch off the usage of engineering strains by setting "EngineeringStrain"False in the parameters pars. This may be of interest when comparing linear material laws with nonlinear material laws, where true stain is used. More information can be found in the reference page of SolidMechanicsStrain.

The St. Venant–Kirchhoff model has limits. The model has poor resistance to forceful compression. As a St. Venant–Kirchhoff elastic body is compressed, it initially reacts with a restorative force. Beyond a critical compression threshold (≈58% of undeformed dimensions along a single axis), the restorative force decreases [15]. In other words, the St. Venant–Kirchhoff model becomes softer when it is compressed.

To give more information on how to write user-defined material laws, it can be instructive to see actual implementations. An example of how to add a user-defined material law, sometimes called UMAT, was shown in the section on hypoelastic materials. The actual implementation of the St. Venant–Kirchhoff material model is given below, and the way this model is constructed can be used as an example for constructing other constitutive models.

MaterialModel[_, "Isotropic", "VenantKirchhoff", vars_, pars_, data__] :=

Module[

{X, dim, lambda, mu, EE, ee, rules, stressMatrix, strainMeasure},

values = GetSolidMechanicsMaterialParameterList[vars, pars,

{"LameParameter", "ShearModulus"}, <||>];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{lambda, mu} = values;

X = vars[[-1]];

dim = Length[X];

EE = Array[ee, {dim, dim}];

stressMatrix = lambda * Tr[EE] * IdentityMatrix[dim] + 2 * mu * EE;

(* get the strain measure *)

strainMeasure = "StrainMeasure" /. data;

rules = Thread[Rule[Flatten[EE], Flatten[strainMeasure]]];

stressMatrix = stressMatrix /. rules;

stressMatrix

]

Adding a New Material Model

Now that a first hyperelastic material model has been examined, the process of creating a new material model can be demonstrated. The previously introduced St. Venant–Kirchhoff model will be used to illustrate how to incorporate it as a custom model.

Once a material model is established, the solid mechanics functions need to be instructed on how to utilize it. This is achieved by specifying the proper parameters in the parameter association.

The "SolidMechanicsMaterialModelFunction" specifies the new material model. The material parameters are the same as above for the St. Venant–Kirchhoff example. As a "StrainMeasure", the "GreenLagrange" strain is used. More information on the available strain measures can be found in the theory section on strain. Next, the stress measure used in the material law needs to be specified for SolidMechanicsPDEComponent. "ConstitutiveStressMeasure" is the stress measure used for the material law. "EquilibriumStressMeasure" is the stress measure of the nonlinear equilibrium equation. For example, to specify the material law with "FirstPiolaKirchhoff" stress, the "ConstitutiveStressMeasure" would then be set accordingly. The "OutputStressMeasure" is, by default, the "Cauchy" stress but can be changed. The conversions between the stresses happen automatically.

Neo-Hookean Model

As the name suggests, the neo-Hookean material model is an extension of the linear elastic Hooke model to large deformations. The energy density function for a compressible neo-Hookean model ![]() is given as [5, p. 499]:

is given as [5, p. 499]:

Various other formulations for the same energy density function exist and are usually based on invariants, for example

where ![]() is the first invariant and

is the first invariant and ![]() , but will not be pursued here. The second Piola–Kirchhoff stress is given as [5, p. 500]:

, but will not be pursued here. The second Piola–Kirchhoff stress is given as [5, p. 500]:

To give more information on how to write user-defined material laws, it can be instructive to see actual implementations. An example of how to add a user-defined material law, sometimes called UMAT, was shown in the section on hypoelastic materials. The actual implementation of the neo-Hookean material law is given in a more detailed section on the neo-Hookean model. The way this model is constructed can be used as an example for constructing other constitutive models.

The neo-Hookean model is a mechanistic model. This means it is derived from the mechanical principles of the material. Sometimes, the coefficients ![]() , where

, where ![]() is the shear modulus, and

is the shear modulus, and ![]() , with

, with ![]() the bulk modulus, are made use of.

the bulk modulus, are made use of.

As an example, a unit cube is used. The cube is under tension in the positive ![]() direction while at the same time fixed at

direction while at the same time fixed at ![]() . The body is stretched by 40%.

. The body is stretched by 40%.

The model under discussion here is a compressible model. This means that the volume of the deformed object may change when under load. A compressible model is in contrast to an incompressible or a nearly incompressible model, which will be discussed later. The default for the implemented hyperelastic material models is to be nearly incompressible. To make use of the model discussed here, the parameter "Compressibility"->"Compressible" has to be specified.

First, try the parametric force increment approach.

Even a small initial increment in the boundary displacement fails to converge. While it is possible to decrease the initial displacement further to get to a converging solution, iterating that solution forward to the 40% stretch is going to take a long time if the step size remains small. As an alternative, the PDE is converted to a time-dependent PDE with an initial condition and a derivative of the initial condition of 0 to time-integrate the PDE model to a fictitious time of 1 unit.

Typically, when specifying the time range for a time-dependent differential equation in NDSolve or its related functions, it is specified as a list of time variable ![]() , the start time and the end time,

, the start time and the end time, ![]() . In the above call to NDSolveValue, the time domain is specified as

. In the above call to NDSolveValue, the time domain is specified as ![]() . Note that

. Note that ![]() is set to

is set to ![]() . This means that the time integration is still performed from the time the initial conditions give to the final time

. This means that the time integration is still performed from the time the initial conditions give to the final time ![]() , but at the same time, this instructs NDSolveValue to just store the last time step

, but at the same time, this instructs NDSolveValue to just store the last time step ![]() in the resulting interpolating function.

in the resulting interpolating function.

In order to make the subsequent processing of the data more efficient, the time-dependent interpolating functions of the displacement are converted to stationary interpolating functions. This is easy to do in this case, since only the last time step is of interest. InterpolatingFunction objects store the solution of all nodes at the various time steps NDSolve has taken in a list. Only the last set of values is extracted from the interpolating function. These values can then be packaged into new interpolating functions.

The volume is larger then the initial volume. More on this topic can be found in the section on Compressibility. The volume increase is, however, small compared to the overall volume.

Note that in the above graphic the bounding box of the graphic is shown and not the original undeformed cube.

The contours are numerical artefacts resulting from the coarse mesh used.

The neo-Hookean model is also used in the Biaxial Tensile Test Hyperelastic Tissue application model.

MaterialModel[_, "Isotropic", "NeoHookeanCompressible", vars_, pars_, data__]:=

Module[

{U, X, dim, lambda, mu, fp, f, idm, c, cinv, j, stressMatrix},

values = GetSolidMechanicsMaterialParameterList[vars, pars,

{"LameParameter", "ShearModulus"}, <||>];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{lambda, mu} = values;

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = idm;

f[[1 ;; dim, 1 ;; dim]] = DeformationGradient[vars, pars];

(* in the plane strain case: f[[3,3]] = 1; *)

If[ pars["SolidMechanicsModelForm"] == "PlaneStress",

f[[3,3]] = Exp[-lambda/(lambda + 2 mu) Log[Det[f[[1;;dim, 1;;dim]]]]];

];

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

stressMatrix = mu * (idm - cinv) + lambda * Log[j] * cinv;

(* Second Piola-Kirchhoff stress *)

Simplify[stressMatrix[[1;;dim, 1;;dim]]]

]

Strain Invariants

The strain energy density function ![]() is often expressed through the Cauchy–Green strain

is often expressed through the Cauchy–Green strain ![]() instead of the deformation gradient

instead of the deformation gradient ![]() . In principal, using the deformation gradient

. In principal, using the deformation gradient ![]() is perfectly fine. The disadvantage, however, is that using

is perfectly fine. The disadvantage, however, is that using ![]() can be unintuitive when designing material models. For example, the compressibility of material models can be expressed well when using a different formulation than the deformation gradient

can be unintuitive when designing material models. For example, the compressibility of material models can be expressed well when using a different formulation than the deformation gradient ![]() to express the energy density function

to express the energy density function ![]() . It is thus common to express

. It is thus common to express ![]() through a strain measure, like the Cauchy–Green strain

through a strain measure, like the Cauchy–Green strain ![]() or though invariants that are derived from the deformation gradient

or though invariants that are derived from the deformation gradient ![]() [15, p. 11ff].

[15, p. 11ff].

The material models should be rotationally invariant. That means the model should give the same result if the object and loads are rotated. A hyperelastic material model is rotationally invariant if and only if the strain energy density function satisfies:

A second property is related to the isotropy of the materials. A material is called isotropic if its material properties are the same in all directions. A hyperelastic material model is isotropic if and only if the strain energy density function satisfies:

where ![]() is a rotation matrix. As a consequence, a material that is both rotationally invariant and isotropic satisfies:

is a rotation matrix. As a consequence, a material that is both rotationally invariant and isotropic satisfies:

Using a singular-value decomposition ![]() , a rotationally invariant and isotropic material satisfies:

, a rotationally invariant and isotropic material satisfies:

where ![]() is the three singular values of

is the three singular values of ![]() , namely

, namely ![]() ,

, ![]() and

and ![]() . The

. The ![]() are called the principal stretches. One could define the strain energy density function

are called the principal stretches. One could define the strain energy density function ![]() in terms of the singular values of

in terms of the singular values of ![]() , but this is not done for isotropic material since the computation of the singular-value decomposition is expensive. Instead, what is done is to use three isotropic invariants

, but this is not done for isotropic material since the computation of the singular-value decomposition is expensive. Instead, what is done is to use three isotropic invariants ![]() ,

, ![]() and

and ![]() of the Cauchy–Green strain tensor

of the Cauchy–Green strain tensor ![]() , which are as good as the singular values but easier to compute. The isotropic invariants are defined as

, which are as good as the singular values but easier to compute. The isotropic invariants are defined as

Here ![]() ,

, ![]() and

and ![]() are the first, second and third isotropic invariants, respectively, and

are the first, second and third isotropic invariants, respectively, and ![]() is the right Cauchy–Green deformation tensor. Note that in the literature, there are at least two ways to define

is the right Cauchy–Green deformation tensor. Note that in the literature, there are at least two ways to define ![]() :

:

The invariants can also be expressed making use of the principal stretches ![]() , which are the singular values of

, which are the singular values of ![]() :

:

A special case can be identified when there is no strain, all the stretches are ![]() and the invariants are constant

and the invariants are constant ![]() ,

, ![]() and

and ![]() , respectively.

, respectively.

In summary, the strain energy density function ![]() can be expressed both in terms of the Cauchy–Green strain and the strain invariants

can be expressed both in terms of the Cauchy–Green strain and the strain invariants ![]() :

:

The invariants return a unique measure of strain that does not depend on rotations and is cheap to compute.

In practice, it is also useful to know the derivatives of the invariants with respect to the right Cauchy–Green strain ![]() [16, p. 216]:

[16, p. 216]:

where ℐ represents the identity matrix.

From this, the second Piola–Kirchhoff stress ![]() can be derived from the invariants

can be derived from the invariants ![]() . For this, the strain energy density function

. For this, the strain energy density function ![]() is expressed though the isotropic invariants

is expressed though the isotropic invariants ![]() . The second Piola–Kirchhoff stress

. The second Piola–Kirchhoff stress ![]() can then be computed through the chain rule as:

can then be computed through the chain rule as:

Using the derivatives of the invariants the expression is simplified to:

Compressibility

One important aspect of the description of materials is their volumetric behavior when they are deformed. Typically compressible, incompressible and nearly incompressible material models are separated. In a compressible material description, the volume of the deformed object is allowed to change. For an incompressible material, the change in volume under deformation is zero. This incompressibility is expressed by the mathematical definition of incompressibility and is given as ![]() .

.

An incompressible material model is, in a way, the equivalent of a linear elastic material with a Poisson ratio of ![]() , where the incompressibility is enforced by requiring that

, where the incompressibility is enforced by requiring that ![]() . A Poisson ratio

. A Poisson ratio ![]() expresses a material behavior in the direction perpendicular to the direction of loading. The Poisson ratio allows the relative change of volume due to the stretch as

expresses a material behavior in the direction perpendicular to the direction of loading. The Poisson ratio allows the relative change of volume due to the stretch as ![]() to be expressed. For incompressible materials, where the volume change is zero

to be expressed. For incompressible materials, where the volume change is zero ![]() , the Poisson ratio has to be

, the Poisson ratio has to be ![]() . This in turn leads to an infinite bulk modulus

. This in turn leads to an infinite bulk modulus ![]() and results in extra stiffness when solving the model. To avoid the numerical difficulty of solving the stiff models, nearly incompressible models have been introduced.

and results in extra stiffness when solving the model. To avoid the numerical difficulty of solving the stiff models, nearly incompressible models have been introduced.

To model incompressible materials, the strain energy density function ![]() is split into an isochoric, constant volume part

is split into an isochoric, constant volume part ![]() and a volumetric part

and a volumetric part ![]() :

:

where ![]() . The isochoric part

. The isochoric part ![]() represents deformations without changes in volume. The volumetric part

represents deformations without changes in volume. The volumetric part ![]() models the incompressibility. In fact, the volumetric part is used to enforce incompressibility.

models the incompressibility. In fact, the volumetric part is used to enforce incompressibility. ![]() is constructed such that it depends only on the volume ratio

is constructed such that it depends only on the volume ratio ![]() . A model that enforces

. A model that enforces ![]() is incompressible.

is incompressible.

![]() is given as

is given as ![]() [16, p. 230]. However, since

[16, p. 230]. However, since ![]() is imposed for incompressibility, this results in

is imposed for incompressibility, this results in ![]() .

. ![]() is used to indicate that the strain energy density function

is used to indicate that the strain energy density function ![]() depends only on isochoric deformations.

depends only on isochoric deformations.

For a fully incompressible material, the volumetric part ![]() is not defined but instead is postulated through a strain energy with a constraint. A hydrostatic pressure

is not defined but instead is postulated through a strain energy with a constraint. A hydrostatic pressure ![]() is introduced to enforce the incompressibility:

is introduced to enforce the incompressibility:

Differentiating ![]() with the chain rule

with the chain rule

gives ![]() and

and ![]() . Then with

. Then with ![]() , this leads to the second Piola–Kirchhoff stress

, this leads to the second Piola–Kirchhoff stress ![]() , which can now be expressed as:

, which can now be expressed as:

In the above differentiation, the isochoric part is differentiated with respect to ![]() , and the second term only depends on

, and the second term only depends on ![]() .

.

Enforcing ![]() exactly can be problematic numerically, since that increases the stiffness of the model. Additionally, it requires an extra degree of freedom. So, instead of aiming for an exact satisfaction

exactly can be problematic numerically, since that increases the stiffness of the model. Additionally, it requires an extra degree of freedom. So, instead of aiming for an exact satisfaction ![]() , the requirement is loosened and the aim is to achieve

, the requirement is loosened and the aim is to achieve ![]() . This is what is called a nearly incompressible model and is a good compromise. The volumetric part is now expressed as:

. This is what is called a nearly incompressible model and is a good compromise. The volumetric part is now expressed as:

to enforce the incompressibility constraint ![]() . The hydrostatic pressure

. The hydrostatic pressure ![]() can be expressed as:

can be expressed as:

where ![]() is the material's bulk modulus. If experimental values for

is the material's bulk modulus. If experimental values for ![]() are not available,

are not available, ![]() can be related to the shear modulus

can be related to the shear modulus ![]() by

by ![]() .

. ![]() is a scale factor and typically in the range

is a scale factor and typically in the range ![]() .

.

k = EstimateBulkModulus[vars, pars, <|s -> 10^4, "ShearModulus" -> mu|>];

p = - k * (j - 1);

The second Piola–Kirchhoff stress for a nearly incompressible material model is:

Hyperelastic Model Collection

The models presented here can be classified into phenomenological, mechanistic and hybrid models. A phenomenological description of a material means that the model is made in such a way that it matches experimental data as closely as possible but does not have a physical basis. In contrast, a mechanistic model is based on physical processes, and one tries to match experimental data. Hybrid models account for both aspects.

All the hyperelastic models presented below have model parameters. Some of them, like the shear modulus, are specified as string parameters like "ShearModulus". Other parameters that do not have names or are part of an equation are given as formal symbol parameters such as ![]() . The notational alphabet guide page explains how to create the formal symbols. As far as the workflow is concerned, the formal symbol variables can just be copied from the examples below.

. The notational alphabet guide page explains how to create the formal symbols. As far as the workflow is concerned, the formal symbol variables can just be copied from the examples below.

A comparison of the hyperelastic material models is available in the Hyperelastic Model Comparison application example.

Mooney–Rivlin Models

The generalized Rivlin hyperelastic model is commonly used to describe the mechanical behavior of rubberlike materials that exhibit significant nonlinear deformations. This model is suitable for materials that undergo large strains and possess isotropic, homogeneous and nearly incompressible properties. It is often employed in applications, including biomechanics, soft tissue mechanics and elastomer engineering and is considered a phenomenological model.

The strain energy density function ![]() of the generalized Rivlin [18] model is given as:

of the generalized Rivlin [18] model is given as:

with ![]() representing material coefficients related to the isochoric response of an applied stress. The coefficient

representing material coefficients related to the isochoric response of an applied stress. The coefficient ![]() is always set to 0, such that

is always set to 0, such that ![]() .

.

The last term in Eqn. (1) is related to the compressible version of the Mooney–Rivlin model, where ![]() is related to the volumetric response due to stress application. Since the current version of the Wolfram Language does not provide a compressible version,

is related to the volumetric response due to stress application. Since the current version of the Wolfram Language does not provide a compressible version, ![]() is set to

is set to ![]() .

.

To make the model consistent with linear elasticity, it is also necessary that the bulk modulus be set to ![]() and the shear modulus be set to

and the shear modulus be set to ![]() .

.

Special combinations of the indices ![]() and

and ![]() of the material coefficients

of the material coefficients ![]() lead to well-known models. For example, the two-parameters Mooney–Rivlin model with

lead to well-known models. For example, the two-parameters Mooney–Rivlin model with ![]() and

and ![]() ,

, ![]() ,

, ![]() or with

or with ![]() leads to the neo-Hookean model. The most commonly used versions are the two-, five- and nine-parameters versions of the Mooney–Rivlin.

leads to the neo-Hookean model. The most commonly used versions are the two-, five- and nine-parameters versions of the Mooney–Rivlin.

The incompressible Mooney–Rivlin model

The strain energy of the Mooney–Rivlin model in Eqn. (2) is a linear combination of the first and second strain invariants and was proposed by Melvin Mooney [19] and then formalized by Ronald Rivlin [18] in terms of the invariants. The most used variants are the two parameters, the five parameters and the nine parameters Mooney–Rivlin models, where the unused coefficients equal zero. The nine-parameter strain energy function reads:

In the five-parameters model, only the coefficients ![]() are used. The strain energy reads:

are used. The strain energy reads:

In the two-parameters model, only the coefficients ![]() and

and ![]() are used. The strain energy reads:

are used. The strain energy reads:

Note that the material parameters are often named ![]() and

and ![]() .

.

The isochoric part depends only on the isochoric strain invariants ![]() . Due to the incompressibility constraint

. Due to the incompressibility constraint ![]() , the first isochoric invariant is

, the first isochoric invariant is ![]() .

.

The isochoric part returns the contribution to the stress as:

The second Piola–Kirchhoff stress ![]() is expressed as:

is expressed as:

A fully incompressible Mooney–Rivlin model is currently not implemented in the Wolfram Language.

The nearly incompressible Mooney–Rivlin model

The second Piola–Kirchhoff stress ![]() of the nearly incompressible, nine-parameters Mooney-Rivlin model reads:

of the nearly incompressible, nine-parameters Mooney-Rivlin model reads:

For the two- and five-parameters version, the Piola–Kirchhoff stress has a similar structure; the unused coefficients equal zero.

The Mooney–Rivlin model parameters ![]() and

and ![]() are related to the shear modulus

are related to the shear modulus ![]() by

by ![]() .

.

To set the bulk modulus ![]() , in the case when no experimental values are available, it is possible to relate

, in the case when no experimental values are available, it is possible to relate ![]() to the shear modulus

to the shear modulus ![]() by

by ![]() .

. ![]() is a scale factor and typically in the range

is a scale factor and typically in the range ![]() . In other words, the shear modulus is used to calibrate

. In other words, the shear modulus is used to calibrate ![]() .

.

The model parameter s is optional and defaults to ![]() . If the parameter "BulkModulus" is given, then

. If the parameter "BulkModulus" is given, then ![]() will be set to that value.

will be set to that value.

What follows is an example of how to use the nearly incompressible Mooney–Rivlin model.

The previous solution is used to start the nonlinear solve for the current solution.

The following visualization is to scale.

The actual implementation of the nearly incompressible Mooney–Rivlin material model is given below, and the way this model is constructed can be used as an example for constructing other constitutive models.

MaterialModel[_, "Isotropic", "MooneyRivlin", vars_, parsIn_, data__] :=

Module[

{dim, f, idm, c, cinv, j, pars, stressMatrix, p, i1, i1iso, C10, C01, C11, C20, C02, C30, C03, C21, C12, k, ciso, mu, s, i2iso, PK2Iso, idg, temp, idgInverse, idgInverseDot, idgJacobian},

pars = parsIn;

If[ KeyExistsQ[pars, Subscript[c, 1]],

pars[Subscript[c, 1, 0]] = pars[Subscript[c, 1]];

];

If[ KeyExistsQ[pars, Subscript[c, 2]],

pars[Subscript[c, 0, 1]] = pars[Subscript[c, 2]];

];

values = GetSolidMechanicsMaterialParameterList[vars, pars, {

Subscript[c, 1, 0], Subscript[c, 0, 1], Subscript[c, 1, 1],

Subscript[c, 2, 0], Subscript[c, 0, 2],

Subscript[c, 3, 0], Subscript[c, 0, 3],

Subscript[c, 2, 1], Subscript[c, 1, 2]

}, <|

Subscript[c, 1, 1] -> 0, Subscript[c, 2, 0] -> 0, Subscript[c, 0, 2] -> 0, Subscript[c, 3, 0] -> 0, Subscript[c, 0, 3] -> 0, Subscript[c, 2, 1] -> 0, Subscript[c, 1, 2] -> 0

|>

];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{C10, C01, C11, C20, C02, C30, C03, C21, C12} = values;

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = ExtendedDeformationGradient[DeformationGradient[vars, pars] ];

idg = pars["InelasticDeformationGradient"];

temp = Through[idg[vars, pars]];

temp = ExtendedDeformationGradient /@ temp;

idgInverse = Inverse /@ temp;

idgInverseDot = Dot @@ idgInverse;

idgJacobian = (Times @@ Det /@ temp);

f = f . idgInverseDot;

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

i1 = Tr[c];

i1iso = i1 * j^(-2/3);

ciso = c * j^(-2/3);

i2iso = (Tr[ciso]^2 - Tr[ciso . ciso])/2;

PK2Iso = 2 ((C10 + 2 C20 (i1iso - 3) + C11 (i2iso - 3) +

2 C30 (i1iso - 3)^2 + 2 C21 (i1iso - 3) (i2iso - 3) +

C12 (i2iso - 3)^2 + i1iso (C01 + C11 (i1iso - 3) +

2 C02 (i2iso - 3) C21 (i1iso - 3)^2 + 2 C12 (i1iso - 3) (i2iso - 3) +

2 C03 (i2iso - 3)^2)) idm - (C01 + C11 (i1iso - 3) +

2 C02 (i2iso - 3)) ciso);

mu = 2 (C10 + C01);

k = EstimateBulkModulus[vars, pars, <|s -> 10^3, "ShearModulus" -> mu|>];

p = - k (j - 1);

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

stressMatrix = PK2Iso - p * j * cinv;

(* pull-back *)

stressMatrix = idgJacobian*idgInverseDot.stressMatrix.Transpose[idgInverseDot];

(* returns second Piola-Kirchhoff stress *)

stressMatrix[[1 ;; dim, 1 ;; dim]]

]

Yeoh Model

The Yeoh model represents a phenomenological description of elastic properties of rubberlike material. This means it describes observed behavior. The model is used for nearly incompressible and incompressible materials. The Yeoh model implemented in the Wolfram Language is a nearly incompressible model.

From Rivlin's theory of rubber elasticity [16, p. 238], it is possible to represent the strain energy function as an infinite power series in the strain invariants. Yeoh made the assumption that ![]() and proposed a function that is cubic in the first strain invariant

and proposed a function that is cubic in the first strain invariant ![]() . This assumption is based on several experiments that show how

. This assumption is based on several experiments that show how ![]() is numerically close to zero [1, p. 245].

is numerically close to zero [1, p. 245].

The strain energy density function ![]() of the Yeoh model is given as:

of the Yeoh model is given as:

where ![]() is the first strain invariant, given as

is the first strain invariant, given as ![]() .

.

There is no compressible version for the Yeoh model because the model is derived from the assumption that ![]() . This means that

. This means that ![]() , and that models incompressibility.

, and that models incompressibility.

The incompressible Yeoh model

The isochoric part of the Yeoh model is:

The isochoric part depends only on the isochoric strain invariants ![]() . Due to the incompressibility constraint

. Due to the incompressibility constraint ![]() , the first isochoric invariant is

, the first isochoric invariant is ![]() .

.

The isochoric part returns the contribution to the stress as:

The second Piola–Kirchhoff stress ![]() is expressed as:

is expressed as:

A fully incompressible Yeoh model is currently not implemented in the Wolfram Language.

The nearly incompressible Yeoh model

The second Piola–Kirchhoff stress ![]() of the nearly incompressible Yeoh model reads:

of the nearly incompressible Yeoh model reads:

The isochoric part of the first strain invariant is expressed as ![]() .

.

To make use of the Yeoh model, it is necessary to specify model parameters for ![]() ,

, ![]() and

and ![]() . What remains is to specify the value of

. What remains is to specify the value of ![]() .

.

The Yeoh model parameter ![]() is related to the shear modulus

is related to the shear modulus ![]() by

by ![]() . To set the bulk modulus

. To set the bulk modulus ![]() , in the case when no experimental values are available, it is possible to relate

, in the case when no experimental values are available, it is possible to relate ![]() to the shear modulus

to the shear modulus ![]() by

by ![]() .

. ![]() is a scale factor and typically in the range

is a scale factor and typically in the range ![]() . In other words, the shear modulus is used to calibrate

. In other words, the shear modulus is used to calibrate ![]() .

.

The model parameter s is optional and defaults to ![]() . If the parameter "ShearModulus" is set and at the same time the model parameter c1 is not given, then

. If the parameter "ShearModulus" is set and at the same time the model parameter c1 is not given, then ![]() will be set to

will be set to ![]() . If the parameter "BulkModulus" is given, then

. If the parameter "BulkModulus" is given, then ![]() will be set to that value.

will be set to that value.

What follows is an example of how to use the nearly incompressible Yeoh model.

The previous solution is used to start the nonlinear solve for the current solution.

The following visualization is to scale.

The actual implementation of the nearly incompressible Yeoh material model is given below, and the way this model is constructed can be used as an example for constructing other constitutive models.

The application example Layered Vascular Vessel with Yeoh Constitutive Model makes use of the Yeoh material model.

MaterialModel[_, "Isotropic", "Yeoh", vars_, parsIn_, data__] :=

Module[

{pars, dim, f, idm, c, cinv, j, stressMatrix, p, i1, i1iso, c1, c2, c3, mu, k,

PK2Iso, idg, temp, idgInverse, idgInverseDot, idgJacobian},

pars = parsIn;

If[ KeyExistsQ[pars, "ShearModulus"],

pars[Subscript[c, 1]] = pars["ShearModulus"]/2;

];

values = GetSolidMechanicsMaterialParameterList[vars, pars, {

Subscript[c, 1], Subscript[c, 2], Subscript[c, 3]}, <||>];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{c1, c2, c3} = values;

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = ExtendedDeformationGradient[DeformationGradient[vars, pars] ];

idg = pars["InelasticDeformationGradient"];

temp = Through[idg[vars, pars]];

temp = ExtendedDeformationGradient /@ temp;

idgInverse = Inverse /@ temp;

idgInverseDot = Dot @@ idgInverse;

idgJacobian = (Times @@ Det /@ temp);

f = f . idgInverseDot;

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

i1 = Tr[c];

i1iso = i1 * j^(-2/3);

PK2Iso = 2 * (c1 + 2*c2*(i1iso - 3) + 3*c3*(i1iso - 3)^2)*IdentityMatrix[3];

mu = 2 * c1;

k = EstimateBulkModulus[vars, pars, <|s -> 10^4, "ShearModulus" -> mu|>];

p = - k * (j - 1);

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

stressMatrix = PK2Iso - p * j * cinv;

(* pull-back *)

stressMatrix =idgJacobian*idgInverseDot.stressMatrix.Transpose[idgInverseDot];

(* returns second Piola-Kirchhoff stress *)

Simplify[stressMatrix[[1 ;; dim, 1 ;; dim]]]

]

Neo-Hookean Model

The neo-Hookean mode has been introduced in a previous section as an extension to linear elasticity. In the following, the incompressible and nearly incompressible versions are described. It is also worth mentioning that the neo-Hookean model is a special case of the Mooney–Rivlin models but is considered a mechanistic model.

The incompressible neo-Hookean model

The strain energy function for the incompressible neo-Hookean contains only the isochoric term of the neo-Hookean model:

The isochoric part depends only on the isochoric strain invariants ![]() . Due to the incompressibility constraint

. Due to the incompressibility constraint ![]() , the first isochoric invariant is

, the first isochoric invariant is ![]() .

.

The isochoric part returns the contribution to the stress as:

The second Piola–Kirchhoff stress ![]() is expressed as:

is expressed as:

A fully incompressible neo-Hookean model is currently not implemented in the Wolfram Language.

Nearly incompressible neo-Hookean model

The second Piola–Kirchhoff stress ![]() of the nearly incompressible neo-Hookean model reads:

of the nearly incompressible neo-Hookean model reads:

The neo-Hookean model is available in a compressible and a nearly incompressible form. The default is the nearly incompressible form. To make use of the compressible neo-Hookean model, it is necessary to specify model parameter ![]() and the parameter "Compressibility"->"Compressibile".

and the parameter "Compressibility"->"Compressibile".

To set the bulk modulus ![]() , in the case when no experimental values are available, it is possible to relate

, in the case when no experimental values are available, it is possible to relate ![]() to the shear modulus

to the shear modulus ![]() by

by ![]() .

. ![]() is a scale factor and typically in the range

is a scale factor and typically in the range ![]() . In other words, the shear modulus is used to calibrate

. In other words, the shear modulus is used to calibrate ![]() . If the parameter "BulkModulus" is given, then

. If the parameter "BulkModulus" is given, then ![]() will be set to that value.

will be set to that value.

What follows is an example of how to use the nearly incompressible neo-Hookean model.

MaterialModel[_, "Isotropic", "NeoHookeanNearlyIncompressible", vars_, pars_, data__] :=

Module[

{U, X, dim, lambda, mu, fp, f, idm, c, cinv, j, PK2Iso, stressMatrix, idg,

temp, idgInverse, idgInverseDot},

If[ KeyExistsQ[pars, Subscript[c, 1]],

mu = 2 * pars[Subscript[c, 1]];

pars["ShearModulus"] = mu;

,(* else *)

mu = GetSolidMechanicsMaterialParameter[vars, pars, "ShearModulus"];

];

If[ FailureQ[mu], Return[ $Failed, Module]; ];

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = ExtendedDeformationGradient[DeformationGradient[vars, pars] ];

idg = pars["InelasticDeformationGradient"];

temp = Through[idg[vars, pars]];

temp = ExtendedDeformationGradient /@ temp;

idgInverse = Inverse /@ temp;

idgInverseDot = Dot @@ idgInverse;

idgJacobian = (Times @@ Det /@ temp);

f = f . idgInverseDot;

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

PK2Iso = mu * idm;

k = EstimateBulkModulus[vars, pars, <|s -> 10^2|>];

p = - k (j - 1);

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

stressMatrix = PK2Iso - p * j * cinv;

(* pull-back *)

stressMatrix = idgJacobian*idgInverseDot.stressMatrix.Transpose[idgInverseDot];

(* Second Piola-Kirchhoff stress *)

Simplify[stressMatrix[[1;;dim, 1;;dim]]]

]

Arruda-Boyce Model

The Arruda–Boyce model is a mechanistic model used to describe polymeric substances. The model is based on the statistical mechanics of a representative elementary cell containing a number ![]() of polymer chains. A cuboid elementary cell, for example, would have eight polymer chains; one from the center to each of the corners. These cells are not related to the finite element mesh but form the basis for the theoretical derivation of the model.

of polymer chains. A cuboid elementary cell, for example, would have eight polymer chains; one from the center to each of the corners. These cells are not related to the finite element mesh but form the basis for the theoretical derivation of the model.

The eight-chain network of the Arruda–Boyce model for a cuboid elementary cell.

The strain energy density function ![]() of the Arruda–Boyce [20] model is given as:

of the Arruda–Boyce [20] model is given as:

Where ![]() and

and ![]() represent, respectively, the number of segments in a single chain and the number of polymer chains in the network,

represent, respectively, the number of segments in a single chain and the number of polymer chains in the network, ![]() is the Boltzmann constant, and

is the Boltzmann constant, and ![]() the absolute temperature in [K]. The chain stretch

the absolute temperature in [K]. The chain stretch ![]() is related to the first stain invariant as:

is related to the first stain invariant as:

The Langevin function ℒ is given as:

ℒ-1 represents the inverse Langevin function and is a function of the chain stretch ![]() , as:

, as:

The use of the Langevin statistics accounts for the limiting chain extensibility based on the chain's entropy.

Computing the inverse Langevin function is computationally expensive. A computationally more efficient version of the strain energy function can be made by approximating the inverse Langevin function with five terms of the truncated Taylor series [20]. The strain energy density function then is then given as:

This version of the strain energy density function also has the ![]() replaced with Eqn. (3), which is a function of the first strain invariant.

replaced with Eqn. (3), which is a function of the first strain invariant.

The model requires two material coefficients: the material constant ![]() and the chain coefficient

and the chain coefficient ![]() related to the chain network locking stretch (

related to the chain network locking stretch (![]() ) as:

) as:

![]() are the numerical coefficients from the Taylor expansion:

are the numerical coefficients from the Taylor expansion:

The incompressible Arruda–Boyce model

The strain energy function reads:

The isochoric part depends only on the isochoric strain invariants ![]() . Due to the incompressibility constraint

. Due to the incompressibility constraint ![]() , the first isochoric invariant is

, the first isochoric invariant is ![]() .

.

The isochoric part returns the contribution to the stress as:

For consistency with linear elasticity, as expressed in the invariants section, the initial shear modulus has to satisfy the condition ![]() that leads to:

that leads to:

The index notation ![]() denotes that in the initial state, for a zero strain, the stretches are

denotes that in the initial state, for a zero strain, the stretches are ![]() . This leads to

. This leads to ![]() .

.

The second Piola–Kirchhoff stress ![]() is then expressed as:

is then expressed as:

A fully incompressible Arruda–Boyce model is currently not implemented in the Wolfram Language.

The nearly incompressible Arruda–Boyce model

The second Piola–Kirchhoff stress ![]() of the nearly incompressible Arruda–Boyce model reads:

of the nearly incompressible Arruda–Boyce model reads:

The isochoric part of the first strain invariant is expressed as ![]() .

.

To make use of the Arruda–Boyce model, it is necessary to specify two material coefficients: the material constant ![]() and the chain coefficient

and the chain coefficient ![]() , which is related to the chain network locking stretch

, which is related to the chain network locking stretch ![]() as

as ![]() .

.

What follows is an example of how to use the nearly incompressible Arruda–Boyce model.

The previous solution is used to start the nonlinear solve for the current solution.

The following visualization is to scale.

The actual implementation of the nearly incompressible Arruda–Boyce material model is given below, and the way this model is constructed can be used as an example for constructing other constitutive models.

MaterialModel[_, "Isotropic", "ArrudaBoyce", vars_, pars_, data__] :=

Module[

{dim, f, idm, c, cinv, j, stressMatrix, p, i1, i1iso, c1, lambdam, k, mu, s, alpha, beta, i1isopower, pp, PK2Iso, idg, temp, idgInverse, idgInverseDot,

idgJacobian},

values = GetSolidMechanicsMaterialParameterList[vars, pars,

{Subscript[c, 1],Subscript[λ, m]}, <||>];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{c1, lambdam} = values;

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = ExtendedDeformationGradient[DeformationGradient[vars, pars] ];

idg = pars["InelasticDeformationGradient"];

temp = Through[idg[vars, pars]];

temp = ExtendedDeformationGradient /@ temp;

idgInverse = Inverse /@ temp;

idgInverseDot = Dot @@ idgInverse;

idgJacobian = (Times @@ Det /@ temp);

f = f . idgInverseDot;

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

i1 = Tr[c];

i1iso = i1 *j^(-2/3);

alpha = {1/2, 1/20, 11/1050, 19/7000, 519/673750};

pp = {0, 1, 2, 3, 4};

beta = Power[1/lambdam^2, pp];

i1isopower = Power[i1iso, pp];

PK2Iso = 2 * c1 * ((alpha * beta) . i1isopower) * idm;

mu = 2 c1 ((pp + 1) * Power[3, pp] * alpha) . beta;

k = EstimateBulkModulus[vars, pars, <|s -> 10^2, "ShearModulus" -> mu|>];

p = - k (j - 1);

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

stressMatrix = PK2Iso - p * j * cinv;

(* pull-back *)

stressMatrix =idgJacobian*idgInverseDot.stressMatrix.Transpose[idgInverseDot];

stressMatrix[[1 ;; dim, 1 ;; dim]]

]

Gent Model

The Gent hyperelastic model is a hybrid model based on the assumption of the existence of a maximum value of ![]() at which the material reaches a limiting state. This state is represented by

at which the material reaches a limiting state. This state is represented by ![]() , and it is assumed to be related to the maximum extension ratios of molecular chains.

, and it is assumed to be related to the maximum extension ratios of molecular chains.

The strain energy density function ![]() of the Gent [21] model is given as:

of the Gent [21] model is given as:

where ![]() is the first strain invariant. For the Gent model, two material parameters are required: the shear modulus

is the first strain invariant. For the Gent model, two material parameters are required: the shear modulus ![]() and the limiting value

and the limiting value ![]() . The limiting value is given as

. The limiting value is given as ![]() , where

, where ![]() is called the locking stretch. For

is called the locking stretch. For ![]() approaching

approaching ![]() , this represents a singularity, and that is why

, this represents a singularity, and that is why ![]() is called a locking stretch.

is called a locking stretch.

The incompressible Gent model

The strain energy function reads:

The isochoric part depends only on the isochoric strain invariants ![]() . Due to the incompressibility constraint

. Due to the incompressibility constraint ![]() , the first isochoric invariant is

, the first isochoric invariant is ![]() .

.

The isochoric part returns the contribution to the stress as:

The second Piola–Kirchhoff stress ![]() is the expressed as:

is the expressed as:

A fully incompressible Gent model is currently not implemented in the Wolfram Language.

The nearly incompressible Gent model

The second Piola–Kirchhoff stress ![]() of the nearly incompressible Gent model reads:

of the nearly incompressible Gent model reads:

The isochoric part of the first strain invariant is expressed as ![]() .

.

To make use of the Gent model, it is necessary to specify model parameters for ![]() and

and ![]() .

.

What follows is an example of how to use the nearly incompressible Gent model.

The previous solution is used to start the nonlinear solve for the current solution.

The following visualization is to scale.

The actual implementation of the nearly incompressible Gent material model is given below, and the way this model is constructed can be used as an example for constructing other constitutive models.

MaterialModel[_, "Isotropic", "Gent", vars_, pars_, data__] :=

Module[

{dim, f, idm, c, cinv, j, stressMatrix, p, i1, i1iso, Jm, mu, k, PK2Iso,

idg, temp, idgInverse, idgInverseDot, idgJacobian},

values = GetSolidMechanicsMaterialParameterList[vars, pars,

{"ShearModulus", Subscript[J, m]}, <||>];

If[ FailureQ[values], Return[ $Failed, Module]; ];

{mu, Jm} = values;

dim = pars["EmbeddingDimension"];

idm = IdentityMatrix[3];

f = ExtendedDeformationGradient[DeformationGradient[vars, pars] ];

idg = pars["InelasticDeformationGradient"];

temp = Through[idg[vars, pars]];

temp = ExtendedDeformationGradient /@ temp;

idgInverse = Inverse /@ temp;

idgInverseDot = Dot @@ idgInverse;

idgJacobian = (Times @@ Det /@ temp);

f = f . idgInverseDot;

j = Det[f];

c = Transpose[f] . f;

cinv = Inverse[c];

i1 = Tr[c];

i1iso = i1 *j^(-2/3);

PK2Iso = (mu * Jm/(Jm - i1iso + 3)) idm;

k = EstimateBulkModulus[vars, pars, <|s -> 10^2, "ShearModulus" -> mu|>];

p = - k (j - 1);

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

stressMatrix = PK2Iso - p*j *cinv;

(* pull-back *)

stressMatrix =idgJacobian*idgInverseDot.stressMatrix.Transpose[idgInverseDot];

stressMatrix[[1 ;; dim, 1 ;; dim]]

]

Plane Strain and Plane Stress Models

For linear elasticity, plane strain and plane stress model forms are implemented. Plane strain and stress model forms can also be devised for hyperelastic models. The linear elastic plane models come with caveats that also apply for their hyperelastic counterparts. Please revisit the Linear Elasticity section for more information.

Plane strain

The starting assumption for the plane strain model is that there is no displacement in the ![]() direction:

direction:

This assumption implies that all strain components that involve the ![]() direction are zero. From the definition of the deformation gradient

direction are zero. From the definition of the deformation gradient ![]() :

:

Now, a reduced two-dimensional deformation gradient ![]() can be represented as:

can be represented as:

Algebraically, these are the same. For example:

This similarity also holds true for other constructs such as the left and right Cauchy tensors and so on. This means that for the plane strain case, the only thing that needs to be done is to set the deformation gradient ![]() such that it has this form:

such that it has this form:

The computations are then performed just like in the 3D case, and at the end the 2×2 subcomponent is extracted.

Plane stress

For the plane stress case, things are more complicated. A plane stress state is characterized by one of the three principal stresses equal to zero. By choosing two coordinate axes arbitrarily but perpendicular to the direction of zero stress, the stress state will have the following structure:

The stress can be represented by a reduced 2×2 matrix ![]() . If the zero stress is in the

. If the zero stress is in the ![]() direction, the stress tensor reads:

direction, the stress tensor reads:

The complication is now to satisfy the plane stress condition. The general ideal to do this is to satisfy the plane stress condition through an out-of-plane deformation, as a change in thickness. For this purpose, an ![]() component is introduced to the deformation gradient, and

component is introduced to the deformation gradient, and ![]() has the form:

has the form:

It is not possible to determine the ![]() component from kinematics; it has to be determined from the constitutive model in question [28]. This means that there is no generally applicable way to do this for all hyperelastic models. The derivation for the compressible and nearly incompressible models is discussed next.

component from kinematics; it has to be determined from the constitutive model in question [28]. This means that there is no generally applicable way to do this for all hyperelastic models. The derivation for the compressible and nearly incompressible models is discussed next.

Following [5, p.502], the three-dimensional relation leads to:

and imposes the requirement of ![]() as follows:

as follows:

Since for the plane stress state, the thickness should be small, the ![]() term should be close to 1. This allows the

term should be close to 1. This allows the ![]() -related term with Taylor expansions to be expressed:

-related term with Taylor expansions to be expressed:

For the nearly incompressible models, a different approach is used. The good news is that this approach works for all nearly incompressible models.

Starting from the second Piola–Kirchhoff stress expressed through a decomposition in an isochoric and a volumetric part:

The isochoric term is given as:

and the volumetric contribution for nearly incompressible materials is given as:

The goal is to find expressions for ![]() and

and ![]() such that plane stress state

such that plane stress state ![]() is satisfied.

is satisfied.

Now, to impose the plane stress condition ![]() , the component

, the component ![]() also needs to be 0, such that

also needs to be 0, such that ![]() . This leads to:

. This leads to:

where the incompressibility constraint ![]() is implicitly considered.

is implicitly considered.

Based on the form of ![]() , the Cauchy–Green tensor

, the Cauchy–Green tensor ![]() has the following form:

has the following form:

Due to the symmetry of ![]() , only four components need to be determined:

, only four components need to be determined: ![]() ,

, ![]() ,

, ![]() and

and ![]() . In addition, the incompressibility constraint

. In addition, the incompressibility constraint ![]() allows the

allows the ![]() component to be expressed as a function of the remaining components as:

component to be expressed as a function of the remaining components as:

Then because of the incompressibility constraint:

Now, ![]() can be expressed in terms of components of

can be expressed in terms of components of ![]() :

:

For isotropic materials, ![]() should be enforced. Both

should be enforced. Both ![]() and

and ![]() are readily available. So,

are readily available. So, ![]() can be expressed as:

can be expressed as:

The Jacobian ![]() is corrected with respect to the reduced form of the deformation gradient as:

is corrected with respect to the reduced form of the deformation gradient as:

With the corrected ![]() and

and ![]() , the second Piola–Kirchhoff stress can now be expressed in the plane stress case:

, the second Piola–Kirchhoff stress can now be expressed in the plane stress case:

In the case of the nearly incompressible models, this is expressed through the following code snippet.

If[pars["SolidMechanicsModelForm"] == "PlaneStress",

j = Det[f] (1/(f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]]));

p = PK2Iso[[1, 1]] /((f[[1, 1]]*f[[2, 2]] - f[[1, 2]]*f[[2, 1]])^2);

];

Plane strain and plane stress comparison

The choice of a plane stress or plane strain model form is set through the "SolidMechanicsModelForm" association key in the parameters pars. The default 2D solid mechanics model form is "PlaneStress".

In the following example, a comparison between the plane stress and strain is presented. A squared domain is fixed on the left side and pulled on the right one.

As mentioned in the section on linear elastic strain, a plane strain model need not necessarily be thick compared to the object's width and breadth. The only requirement is that the ![]() -direction endpoint are not constrained in the

-direction endpoint are not constrained in the ![]() -

-![]() plane.

plane.

The deformed meshes show different displacement for the two different models. The plane strain one, due to the implicit constraints on the deformation on the ![]() direction, appears stiffer than the plane stress, showing a reduced displacement along the pulling direction.

direction, appears stiffer than the plane stress, showing a reduced displacement along the pulling direction.

Hyperelastic Model Calibration

To use a hyperelastic material model, the model parameters either come from literature or are fitted to experimental data. For selecting an appropriate hyperelastic model, experimental data is crucial. Mechanical tests, such as uniaxial tension, compression or shear tests, are conducted to measure the material's stress-strain response under different loading conditions. The data obtained from these tests can then be used to find appropriate model parameters for a specific hyperelastic material model. In a final step, one can then assess how well a particular hyperelastic material model represents the actual experimental data. All these steps can conveniently be done in the Wolfram Language and are explained in this section.

An application model of a Biaxial Tensile Test of a Hyperelastic Tissue is also available.

Uniaxial Test Data Fitting