Solid Mechanics

| Contents | Solid Mechanics Boundary Conditions |

| Introduction | Appendix |

| Overview Example and Analysis Types | Nomenclature |

| Equations | References |

Contents

Introduction

The analysis and behavior of solids under loads and constraints is of fundamental importance in mechanics. Solid mechanics deals with the mechanics of solid bodies in three dimensions, while the topic of structural mechanics encompasses a wider range of objects, such as thin shells or beams, for example.

This tutorial gives an introduction to modeling solid mechanics with partial differential equations. Equations and boundary conditions that are relevant for performing solid mechanics analysis are derived and explained.

Modeling solid mechanics with partial differential equations (PDEs) is not the only way to model solid mechanics. Other techniques include setting up ordinary differential equations (ODEs). This approach is followed by the Wolfram System Modeler. Roughly speaking, the system modeler approach is more suitable for large systems of solid bodies interacting, while the partial differential equation approach is more suitable for a fine-grained analysis of a specific body. In some cases, it is beneficial to use a combination of the two approaches.

The approach taken here is that in an introductory section, a single solid body, a bookshelf bracket, is used to introduce various solid mechanics analysis types and the functionality available. This will be followed by a more theoretical explanation of the underlying ideas and concepts. The theoretical background is much easier to understand once an intuition for the various analysis types exists. After that, the available boundary conditions are discussed.

Solid mechanics typically considers three-dimensional solid objects. Special cases exist to deal with two-dimensional simplifications. These simplifications, however, have some pitfalls that are avoidable if the understanding for the three-dimensional scenario is correct. For this reason, the initial examples will be three-dimensional examples. At a later stage, plane (two-dimensional) stress and strain and their limitations will be introduced.

The goal of a solid mechanics analysis is to find the deformation of a body under load. A subsequent step then finds strains and stresses within the deformed body. The analysis and interpretation of these physical quantities are useful to create a better quality engineering design of the body under consideration. For example, structurally weak parts of an object can be identified and improved upon.

The solid mechanics analysis process is typically done in stages. First, for the body to be analyzed, a geometric model needs to be created. The geometric model is typically created within a computer-aided design (CAD) process. CAD models can either be imported or created in product. To import geometries, common file formats like DXF, STL or STEP are supported. These geometries can be imported with Import. The alternative is to create the geometrical models in product, for example, by using OpenCascadeLink. Once the geometric model is made available, some thought needs to be put into what type of analysis is to be performed. Currently supported analysis types are static analysis, time-dependent analysis, eigenmode analysis and frequency response analysis. The next step is the setup of boundary conditions and constraints. Materials to be used further specify the PDE model. Once the PDE model is fully specified, the subsequent finite element analysis will then compute the desired quantities of the body under investigation. These quantities are then post-processed, either by visualizing them or some derived quantities are computed. This tutorial shows the necessary steps for everything except the CAD model generation.

The modeling process as such results in a system of partial differential equations (PDEs) that can be solved with NDSolve, ParametricNDSolve and NDEigensystem.

The accuracy and the effectiveness of the solid mechanics PDE model is validated in the separate documentation entitled Solid Mechanics Model Verification Tests.

Many of the animations of the simulation results shown here are generated with a call to Rasterize. This is to reduce the disk space required. The downside is that the visual quality of the animations will not be as crisp as without it. To obtain high-quality graphics, remove or comment out the call to Rasterize.

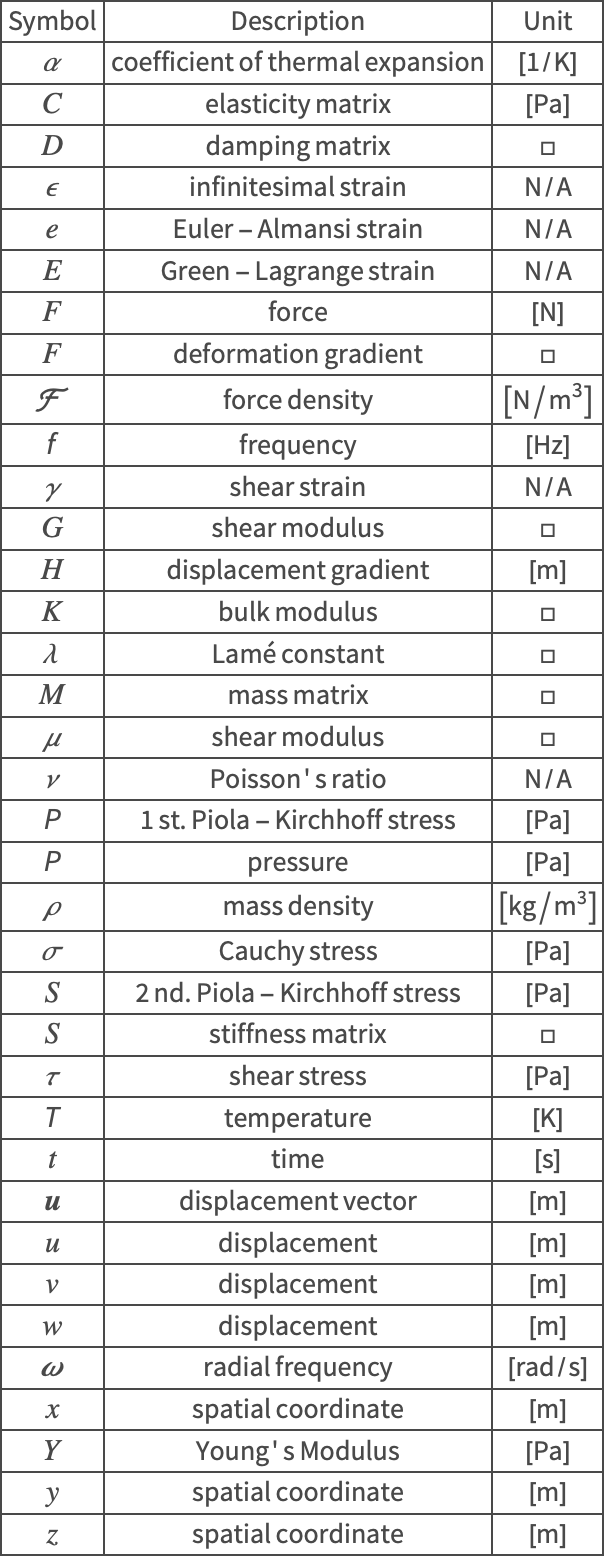

The symbols and corresponding units used throughout this tutorial are summarized in the Nomenclature section.

Overview Example and Analysis Types

To illustrate the usage of the finite element method in solid mechanics, it is instructive to present a simple example and give an overview of the setup, various analysis types and post-processing steps possible.

The first example introduces the workflow of setting up a simple solid mechanics PDE model. Subsequent sections will then use more sophisticated and complete models. For now, consider the following setup with a long beam fixed at the left and with a downward force applied at the right side.

Creating a solid mechanics model always comprises the same steps:

The dependent variables ![]() ,

, ![]() and

and ![]() represent the displacement in the

represent the displacement in the ![]() ,

, ![]() and

and ![]() directions, respectively.

directions, respectively.

The output has been abbreviated since it is large and hard to read, but this is why using the PDEModel components is convenient.

In many cases like this there is no need to generate a mesh; passing the geometry to the solver is sufficient.

VectorDisplacementPlot3D will automatically rescale the deformation to make it visible. The actual, very small deformation can be seen by specifying the option VectorSizes Full. For this reason it is useful to plot a legend that quantifies the displacement.

This gives an overview of the workflow. The next sections describe the steps in more detail on a more elaborate geometric model.

Geometry

For the following overview of available solid mechanics analysis types, a predefined boundary element mesh is loaded. For more information on how this boundary element mesh was generated, refer to the Bookshelf Bracket tutorial, which explains the creation of this specific geometric model.

Sometimes it is useful to check the imported boundary mesh for defects. If defects are found, a legend with the defects will be displayed. In this case, no defects are found.

One thing to keep in mind is the scale used in the geometric model. If the length of the boundary mesh is, for example, in units of meters, then the material parameters will need to be specified in consistent units. In this specific case, the units of the boundary mesh are in meters, so the bracket is 0.2 meters long.

The amount of detail of the geometry will affect the number of elements a finite element mesh will need to represent that geometry. The number of elements in a mesh has a direct influence on the CPU time and memory needed to solve a particular problem. To reduce the number of elements, one can consider that geometric details, such as the screw holes, often only have an influence in their closer surroundings [11, c.1]. Saint Venant's principle suggests that a detail with a characteristic length ![]() will affect the surroundings in a distance of about

will affect the surroundings in a distance of about ![]() . If one is interested in the mechanical performance of the object in a specific region that is far enough away from a particular detail, that detail might be left out of the geometric model and thus save computational effort. Also for vibration analysis, geometric details that are smaller than about 10% of the geometric cross section can usually be neglected.

. If one is interested in the mechanical performance of the object in a specific region that is far enough away from a particular detail, that detail might be left out of the geometric model and thus save computational effort. Also for vibration analysis, geometric details that are smaller than about 10% of the geometric cross section can usually be neglected.

In this case, the bracket geometry does not have a screw thread. This will be taken care of when specifying the boundary conditions.

Generally speaking, one should start with as simple a geometric model as possible and only add details to see if and how they affect the overall solution.

More information on generating or importing 3D geometric models can be found in the Using OpenCascadeLink tutorial.

Material Parameters

The next step is to assign material parameters. Generally, all parameters for a solid mechanics model are collected in an Association pars that includes the necessary parameter values.

A more convenient way to do material parameter setup is to select a material from an Entity. A convenient way to get to an Entity is it make use of the free-form input for WolframAlpha.

Material parameters where the values are given as Quantity objects can be used. Should a material not be available or different units be needed, then the material properties can be added by specifying parameters like YoungModulus and PoissonRatio directly. The exact property names needed can be found on the reference page of SolidMechanicsPDEComponent.

The default material model is a linear elastic isotropic material. As a rule of thumb, a linear elastic material model is applicable until a maximal stretching of 5% is reached [8, p. 159].

Geometries consisting of several materials can also be used, and an example of such a use case is presented in the section on multiple materials.

Units

Should the units of the geometry be different from the material units, then the material units can be scaled.

Internally, all material data units are converted to "SIBase" units. As a consequence, the default unit of length is "Meters". If the units of the geometry are also in meters, then nothing needs to be changed. If the units of the geometry are not in meters, then either the PDE and material properties need to be scaled to the units the geometry or the geometry needs to be scaled to "Meters". To scale the units of the PDE and material parameters, the parameter "ScaleUnits" can be given. If not explicitly stated otherwise, examples in this tutorial use the default "SIBase" units.

Boundary Conditions

Since solid mechanics is about the deformation of objects under load and constraints, boundary conditions are an essential component of solid mechanics modeling. A boundary load is a force or pressure that is applied on the surface of an object. For a load to be applicable to an object, that object must also be constrained in some way, for example, screwed to a wall, as otherwise the object would not pose a resistance to the load. Loads and constraints are set up by specifying boundary conditions. Various boundary conditions can be used and will be discussed in more detail in the boundary conditions section. For the purpose of this overview, a boundary surface load and the constraints introduced by a wall and screws will be sufficient.

The purpose of this section is to establish the positions where the boundary conditions are to be applied. The positions of boundary conditions applied will remain the same, regardless of the analysis type performed. The exact specification of the values of the boundary conditions, however, depends on the different analysis types and will follow in the respective sections.

A way to find the positions where the boundary conditions apply is to visualize them together with the outline of the geometry defined previously in the geometry section.

In a next step, a constraint is added to specify that the bracket is mounted to a wall. To fix the bracket to the wall, two constraints play a role. First, the back of the bracket cannot penetrate the wall and second, screws fix the bracket to the wall.

The screws impose a constraint such that the movement of the surfaces that make the screw hole is prohibited in all directions. This means at the points of contact of the screw and the bracket, no movement is possible at all.

The bracket cannot penetrate the wall, and thus a constraint of the movement of the back of the bracket in the negative ![]() direction is added. Because the two screws press the bracket to the wall and the bracket cannot bend into the wall, a reasonable approach is to also limit the movement in the positive

direction is added. Because the two screws press the bracket to the wall and the bracket cannot bend into the wall, a reasonable approach is to also limit the movement in the positive ![]() (out from the wall) direction. This is a common simplification. If this simplification is not justified, then a contact problem arises.

(out from the wall) direction. This is a common simplification. If this simplification is not justified, then a contact problem arises.

Next, the constraint for the screws is described.

Two large enough cylindrical regions are used to cover the screw holes and chamfer.

For more complicated geometries, a different technique to specify boundary condition predicates may be appropriate and is given in the appendix in the section Boundary Condition Predicates.

Mesh Generation

To perform a finite element analysis, the boundary mesh representation of the geometric model needs to be discretized into a mesh.

More information about the mesh generation process can be found in the Element Mesh generation tutorial. Another option is to import a mesh. Some common mesh file formats can be imported with the help of the FEMAddOns.

Stationary Analysis

A solid mechanics analysis will seek the displacement of an object, which is a consequence of applied forces and constraints. The dependent variables for the displacement are called ![]() ,

, ![]() and

and ![]() and represent the displacements in the

and represent the displacements in the ![]() ,

, ![]() and

and ![]() axis directions, respectively.

axis directions, respectively.

The default setup generates a model for a linear elastic isotropic material with a small deformation assumption. This model does not include the self-weight of the object. This can be added with the parameter "BodyLoadValue". Adding that is explained in the section Body Load.

The result is a list of three InterpolatingFunction objects. Each InterpolatingFunction gives the displacement for its respective dependent variable. The three InterpolatingFunction objects make up the displacement vector.

More information about the solution process and its options can be found in the NDSolve Options for Finite Elements tutorial.

Post-processing

The primary solution of a solid mechanics PDE model is the displacement that results due to the acting forces. This displacement can be used to visualize how the body deforms under the load and constraints. Also of interest are, however, the stresses and strains in the object. The strains in the body are recovered from the displacement. The stresses are then recovered from the strains. So both the strain and stress are secondary unknowns. The recovered strains and stresses can furthermore be combined in overview concepts like the equivalent strain or the von Mises stress. The terminology post-processing is an umbrella term for all computations and visualizations done after the displacements have been computed.

Deformations

The displacements are often termed ![]() ,

, ![]() and

and ![]() and are the computed displacements in the

and are the computed displacements in the ![]() ,

, ![]() and

and ![]() directions, respectively. Sometimes a displacement vector

directions, respectively. Sometimes a displacement vector ![]() is used.

is used.

The deformation of an object under load is simply the computed displacement added to the coordinates of the original object. A point ![]() in an object originally at

in an object originally at ![]() is moved to

is moved to ![]() when the object is under load.

when the object is under load.

The deformation shown is scaled by the minimal size of the geometries' extension and the maximal displacement. This can be switched off or changed by specifying a "ScalingFactor" for ElementMeshDeformation. For more information, see the Element Mesh Visualization tutorial.

ElementMeshDeformation by default will make the deformation visible, regardless how small it is, as long as it is nonzero; however, the visualization does not depict the true deformation. The true deformation can be shown by setting "ScalingFactor"->None.

In most cases, deformations are small, and so "ScalingFactor"->None will not give an interesting plot.

Another consequence of the automatic scaling factor computation is that if the body load is increased, the deformation plot will remain the same, as the values will be scaled back again. The value of the deformation plot is in seeing how the body deforms. This can give an idea if the model works as expected.

Sometimes it is useful to know the value of the automatic scaling factor computed.

Inspecting the total displacement is a way to get an overview of the displacement of a constrained object under load. The total displacement is given by:

where ![]() ,

, ![]() and

and ![]() are the computed displacements in the

are the computed displacements in the ![]() ,

, ![]() and

and ![]() directions, respectively.

directions, respectively.

Strains

Strain is a quantity that describes the amount of deformation within a body [2] and is a ratio and unitless. Strain is not to be confused with the amount of displacement. Strain is related to the displacement by the gradient of a given displacement. The concept of strain will be explained in more detail in the theory section about strain.

The SolidMechanicsStrain function computes the normal and shear strains for each independent direction. The function returns a SymmetrizedArray that contains an expression representing the strain components in the various directions. The SymmetrizedArray enforces symmetry when present and is compact. The strains returned have the following order:

where the normal strains are denoted by ![]() and the shear strains by

and the shear strains by ![]() . The software uses engineering strains by default and

. The software uses engineering strains by default and ![]() . It is possible to switch off the usage of engineering strains by setting "EngineeringStrain"->False in the parameters pars. This may be of interest when comparing linear material laws with nonlinear material laws, where true stain is used. More information can be found in the reference page of SolidMechanicsStrain.

. It is possible to switch off the usage of engineering strains by setting "EngineeringStrain"->False in the parameters pars. This may be of interest when comparing linear material laws with nonlinear material laws, where true stain is used. More information can be found in the reference page of SolidMechanicsStrain.

Loosely speaking, strain is the gradient of the displacement. Strain plots show where the gradient of displacement is large, not where there is much deformation.

Note in this example the absolute values of the strain in the ![]() direction are smaller than absolute values in the

direction are smaller than absolute values in the ![]() direction, even though the displacement in the negative

direction, even though the displacement in the negative ![]() direction is much larger than in the positive

direction is much larger than in the positive ![]() direction.

direction.

Sometime it is useful to visualize the strain results with the same color scale. The minimum and maximum of all strain values are extracted and used to set the bounds for the color scale.

Sometimes one would like to identify the regions where strains are larger than a specific value.

Inspecting all strain components can be cumbersome. The equivalent strain is a simplification that combines all strain components into a scalar, and as such is easier to grasp. However, the equivalent strain does not include the complete picture of the strains.

The equivalent strain computes:

Some implementations of the equivalent strain use a factor of ![]() , where

, where ![]() is Poisson's ratio. This factor has been excluded to ensure the equivalent strain is compatible with the von Mises stress, which is the stress analog of the equivalent strain.

is Poisson's ratio. This factor has been excluded to ensure the equivalent strain is compatible with the von Mises stress, which is the stress analog of the equivalent strain.

Sometimes it is more convenient to plot the strain over the deformed body.

Principal strain values are the main strain values. They are the computed eigenvalues of the strain matrix and correspond to a local coordinate system where the shear strains ![]() are 0. The principal strain values are the

are 0. The principal strain values are the ![]() in the local coordinates and give the load direction independent strains.

in the local coordinates and give the load direction independent strains.

Principal strain values are ordered according to their size.

At each evaluation coordinate, there are three principal strains. Each of those principal strains can be interpreted as a vector and visualized.

The section Boundary Load: Tension has an example that shows the use of PrincipalEigensystem to find stresses in a nonaxial loaded cylinder.

Stresses

Stress is a quantity that describes the distribution of internal forces within a body [2] and is measured in ![]() or

or ![]() .

.

The Stress function computes the normal stress and shear stress for each independent direction. The function returns a SymmetrizedArray that contains an expression representing the stress component in that direction. The stresses returned have the following order:

where the normal stresses are denoted by ![]() and the shear stresses by

and the shear stresses by ![]() . The first index tells you the direction of the force, while the second index specifies the direction of surface the force is acting on.

. The first index tells you the direction of the force, while the second index specifies the direction of surface the force is acting on.

Inspecting all stress variables can be a cumbersome. A simplification that combines all stress components in a single expression is the von Mises stress. The von Mises stress is a scalar and as such, easier to grasp. However, the von Mises stress does not include the complete picture of the stresses present within a body. The von Mises stress is to the stresses the same as the equivalent strain is for the strains.

The von Mises stress computes:

Sometimes it is more convenient to plot the stresses over the deformed body.

Principal stress values are the main stress values. They are the computed eigenvalues of the stress matrix and correspond to the diagonal stress values ![]() where the shear stresses

where the shear stresses ![]() are 0. The principal stress values give stresses independent of load direction.

are 0. The principal stress values give stresses independent of load direction.

Evaluated at a coordinate, ![]() returns a list of three values: the first, second and third principal stress values.

returns a list of three values: the first, second and third principal stress values.

A legend is not meaningful here, as an eigenvector multiplied by a scalar is still an eigenvector.

The section Boundary Load: Tension has an example that shows the use of PrincipalEigensystem to find stresses in a nonaxial loaded cylinder.

Since PrincipalEigensystem sorts the eigenvalues from largest to smallest, it cannot be used for a symbolic computation of principal eigenvalues, as sorting of symbolic expressions is not possible.

Safety factor

The factor of safety is a number telling us by how large a factor the maximal resulting stresses are below a stress limit. There are multiple definitions of the factor of safety, abbreviated as FOS. Because the material at hand is a metal, which is ductile and not brittle, the von Mises failure criterion is a reasonable choice. For ductile materials, failure is considered to start at the onset of plastic deformation (while for brittle materials, failure is considered at fracture). For more information, see the section Failure Theory.

The principal eigenvalues of a stressed body are computed to transform the stresses into load direction independent stresses, which then can be used to compute the von Mises stress.

The equivalent von Mises stress can be computed with the von Mises stress functions if the shear stresses are set to 0.

For ductile material, plastic deformation starts when the stress reaches the yield strength (for brittle materials, when stress reaches the ultimate strength).

A safety factor below one is problematic. In this case, a linear stress-strain relation is assumed; the maximum equivalent stress may be different if a nonlinear stress-strain relation is used. When a linear material model is used outside its realm of validity, the stresses computed are typically higher than the actual stresses. Nevertheless, finding stresses that are higher than the yield stress is something to be very cautious about.

Reaction forces

Every object that is constrained and at the same time under load will have reaction forces that balance the sum of the loads. These reaction forces will be at the constrained parts of the body.

The function PDEModels`ReactionForce returns the displacements just as a normal call to NDSolve would and a second set of InterpolatingFunction instances that are the reaction forces.

The sum of the reaction forces matches the values of the boundary loads.

The shown reaction forces counteract the (not shown) downward force that acts on the bracket.

In the current version, the reaction forces can only be computed for linear stationary solid mechanics models.

Time-Dependent Analysis

A time-dependent analysis will have to be used if some of the PDE model components have time-dependent behavior. A common time-dependent component is time-dependent boundary conditions.

An important numerical aspect of dynamically loading an object is that the load is not applied instantaneously. For one thing, such a model is unphysical and will result in long simulation times.

Since the time-dependent solid mechanics equations are second order time dependent, the initial conditions comprise an initial displacement and an initial velocity field. Note that the initial conditions affect the whole body. For example, specifying a nonzero initial displacement means the entire body is displaced by the specified amount at the initial time.

To monitor the movement of a specific point within the body over time, a query point is set up. The query point can then be traced through time.

Note that the system is not damped and the amplitude of the displacement remains the same over the cycles.

A time-dependent analysis can take a long time and require a lot of memory. For this reason, it is important to be able to estimate if an analysis really needs to be transient. The time ![]() it takes for a shear wave to travel though an elastic solid with a characteristic length

it takes for a shear wave to travel though an elastic solid with a characteristic length ![]() is approximately [11, c.1]

is approximately [11, c.1]

where ![]() is the mass density and

is the mass density and ![]() is the shear modulus. Stress values decay to their stationary values in about

is the shear modulus. Stress values decay to their stationary values in about ![]() . Similar considerations can be made for stresses induced by acceleration in rotating objects [11, c.1].

. Similar considerations can be made for stresses induced by acceleration in rotating objects [11, c.1].

Eigenmode Analysis

An eigenmode analysis computes the resonant frequencies of an object. These frequencies are also called natural frequencies. At each of these eigenfrequencies, the object under investigation deforms into a distinct shape called eigenmode. The result of an eigenmode analysis is a list of frequencies and their corresponding modes.

There are multiple reasons to compute eigenfrequencies and eigenmodes; among them are:

- Objects in resonance are a common cause of failure. Knowing these frequencies helps avoid the shapes being exposed to them.

The generalized equations of motion for solid mechanics for a linear elastic material are given as:

where ![]() is the mass matrix,

is the mass matrix, ![]() the damping matrix,

the damping matrix, ![]() the stiffness matrix and

the stiffness matrix and ![]() the load vector.

the load vector. ![]() is the displacement vector of dependent variables

is the displacement vector of dependent variables ![]() ,

, ![]() and

and ![]() .

. ![]() is the derivative of the displacement vector, the velocity vector, and

is the derivative of the displacement vector, the velocity vector, and ![]() the second derivative of the displacement, the acceleration. For vibrational analysis, the damping

the second derivative of the displacement, the acceleration. For vibrational analysis, the damping ![]() is generally ignored [7] and results in:

is generally ignored [7] and results in:

In an eigenfrequency analysis, constraints are considered but loads are not considered, thus ![]() .

.

For an eigenfrequency analysis, one is interested in the solution of an equation of this form:

Here, ![]() is the solid mechanics PDE component operator that provides

is the solid mechanics PDE component operator that provides ![]() and

and ![]() .

. ![]() is the eigenvalue

is the eigenvalue ![]() .

.

It is worthwhile noting that contrary to other analysis types, the eigenmode analysis needs to be specified as a parameter. In the other cases, SolidMechanicsPDEComponent can deduce the analysis type from the variable specification. The eigenmode analysis is very similar to the time-dependent setup and cannot be deduced from the variable input alone.

First, a contained eigenmode analysis is investigated. This means the body is constrained by boundary conditions. The only conditions relevant for a constrained eigenmode analysis are boundary conditions that result in DirichletCondition where a dependent variable is set to 0. Boundary forces and nonzero SolidDisplacementCondition are not relevant.

The eigenvalues ![]() are related to the angular frequencies

are related to the angular frequencies ![]() by:

by:

The angular frequency is related to the frequency ![]() measured in

measured in ![]() by:

by:

The natural frequencies can be computed from the eigenvalues by:

The amount of the deformation in the deformed shapes is not actual deformations. Keep in mind that the amplitude for the deformations shown is arbitrary. Any constant times an eigenmode is still the same eigenmode. An eigenmode analysis computes the eigenfrequency and the qualitative shape of the modes at the respective frequencies.

A special situation occurs when there are no constraints on the object. Then the first modes will be zero and are called rigid body modes. A rigid body mode represents a body that translates or rotates without deformations. Eigenvalues and modes capture the fundamental shape of deformations a body is capable of. A zero eigenmode accounts for the fact that the body could translate or rotate. The fact that a body can translate or rotate is not news, and thus these modes are of no interest. In three dimensions, there are six rigid body modes, three for the translation in each direction and three for a rotation around each axis.

Note that the first six eigenvalues are relatively close to 0 and represent the rigid body modes. Also note that rigid body modes can have eigenvalues with small imaginary parts.

These are the rigid body modes. A rigid body that is translated or rotated has a zero eigenvalue. All in all, there are three possible translations in the corresponding ![]() ,

, ![]() and

and ![]() axis directions and three rotations around the same axis. The eigenmodes found by the eigensolver are not the pure rigid body modes but are a superposition of combinations of the fundamental rigid body movements.

axis directions and three rotations around the same axis. The eigenmodes found by the eigensolver are not the pure rigid body modes but are a superposition of combinations of the fundamental rigid body movements.

If a modal analysis reveals rigid body modes, then the object is not constrained enough. An eigenanalysis is a good check to verify that the body is sufficiently constrained.

Parametric Analysis

Sometimes one would like to vary a parameter of a PDE model and repetitively solve the same PDE for a variety of parameters. A convenient way to do so is a parametric analysis. In the bookshelf example, it might be of interest how the bookshelf deforms under various surface loads. In this case, the boundary load force is made a parameter. The simulation is set up in exactly the same way as in a nonparametric analysis, only using the ParametricNDSolve family of functions and specifying the name of the parameter in the model.

Note that the results remain qualitatively the same, but the magnitude of the total displacement changes linearly with the force applied.

Force displacement plot

A parametric analysis can be use to create force-displacement plots. For a specific query point, the displacement is tracked while the force increases.

A linear behavior between force and displacement is observed, which is expected for the linear material model that is used by default.

Parametric material laws

It is possible to have parametric material laws. For example, the Poisson ratio, or a heat transfer coefficient could be parametric. These cases work like any other parametric case. The only thing to be aware of is that material law parameter values need to be respecified when computing the strain and stress.

In this case, the strain computation does not depend on the Poisson ratio parameter ![]() and can be done in the usual way.

and can be done in the usual way.

The stress computation, however, does depend on the Poisson ratio parameter ![]() . In this case, the parametric parameters need to have the actual parameter value for the computation. This can be done by replacing the symbolic parameter value with the actual value.

. In this case, the parametric parameters need to have the actual parameter value for the computation. This can be done by replacing the symbolic parameter value with the actual value.

Frequency Response Analysis

A frequency response analysis gives information on how a specific point in a body reacts to a sweep through a frequency range. The result of a frequency response analysis is a frequency response plot showing the relation between real displacement at the range of frequencies. The frequency response analysis is also called harmonic analysis.

Before performing a frequency response analysis, it can be useful to perform an eigenmode and a static analysis. The eigenmode analysis will find the critical frequencies and their related modes that will play a part in the frequency response analysis. The static analysis will provide the maximum displacement without any frequency component.

In the solid mechanics domain, a frequency response analysis in effect solves:

Here ![]() is the angular frequency,

is the angular frequency, ![]() the imaginary init and

the imaginary init and ![]() the resulting displacement.

the resulting displacement. ![]() ,

, ![]() and

and ![]() are the mass, damping and stiffness of the solid mechanics PDE. These are provided by SolidMechanicsPDEComponent.

are the mass, damping and stiffness of the solid mechanics PDE. These are provided by SolidMechanicsPDEComponent.

In this case, like above, the undamped case such that ![]() is considered.

is considered.

To perform a frequency response analysis, a frequency-dependent load or constraint needs to be set up. This is in contrast to an eigenmode analysis, where boundary loads are not relevant.

The remaining boundary conditions are the stationary boundary conditions.

Choose a frequency range from the minimal eigenfrequency to the largest eigenfrequency computed.

To get a better understanding of the result, frequency responses are compared with the stationary solution. For the frequency response analysis, a frequency-dependent load

ofClose to the resonance frequency, the maximal displacement of the query point is about one order of magnitude larger than the displacement of that same point in the stationary analysis.

In the previous section, the eigenvalues of the constrained bookshelf were computed.

Overall, this means that when the body is in resonance, the amount of deformation can be much larger than what is caused by a comparable stationary force.

Note that evaluating the parametric harmonic function at the resonant frequencies computed during the eigenmode analysis may not be possible.

Equations

Overview

Solid mechanics is the analysis of bodies under load and constraints. The entire topic of solid mechanics hinges around four components:

These components are related in the following manner:

Before going into too much detail, a broad overview of the different solid mechanics components is shown.

Equilibrium equations

The equilibrium equations relate a force density ![]()

![]() and the stress

and the stress ![]()

![]() . Loosely speaking, stress

. Loosely speaking, stress ![]() is the resistance of an internal point to the applied load. The time-dependent equilibrium equation is given by:

is the resistance of an internal point to the applied load. The time-dependent equilibrium equation is given by:

where ![]() is the mass density and

is the mass density and ![]() the displacement vector. A load

the displacement vector. A load ![]() can either be acting on the entire body or the boundary. To simplify things, the time-dependent term is ignored for now. The component form of the time-independent equilibrium equation

can either be acting on the entire body or the boundary. To simplify things, the time-dependent term is ignored for now. The component form of the time-independent equilibrium equation ![]() in three-dimensional space for the stress components

in three-dimensional space for the stress components ![]() and body forces

and body forces ![]() is given by:

is given by:

Kinematic equations

The kinematic equations relate the displacement ![]() to the strain

to the strain ![]() . Strain

. Strain ![]() describes the relative displacement between points in the body. There are various strain measures. Here, two approaches are distinguished. In the infinitesimal deformation theory, it is assumed that the displacements and strains are small. This is the default method in SolidMechanicsPDEComponent. The infinitesimal strain measure is given by:

describes the relative displacement between points in the body. There are various strain measures. Here, two approaches are distinguished. In the infinitesimal deformation theory, it is assumed that the displacements and strains are small. This is the default method in SolidMechanicsPDEComponent. The infinitesimal strain measure is given by:

For the finite deformation theory, no assumptions are made. If the strain-displacement relation is nonlinear, it is referred to as geometric nonlinearity. The finite deformation theory is such a geometric nonlinearity. Geometric nonlinearity is also called a nonlinear kinematic equation. A geometric nonlinearity accounts for the fact that the geometry is evolving during the loading.

Constitutive equations

The relation of the equilibrium equations—the forces—and the kinematic equations—the description of deformation—is done through the constitutive equations. The constitutive equations, also known as the material model, relate stress to strain. Generally speaking, this is a relationship of the form

where a function ![]() relates the strain and other field quantities to the stress. The most important relation is Hooke's law, where the relation between stress and strain is linear and given by:

relates the strain and other field quantities to the stress. The most important relation is Hooke's law, where the relation between stress and strain is linear and given by:

where the proportionality constant ![]() is the Young's modulus. Most metals and alloys can be modeled as an elastic material if the strains remain small.

is the Young's modulus. Most metals and alloys can be modeled as an elastic material if the strains remain small.

If a linear relation between stress and strain cannot be assumed, a nonlinear constitutive equation is present. This is also referred to as a nonlinear material law.

Besides linearity, there are other properties of interest in a material law. The deformation of an object is called elastic if after removing a force, the object returns to its original configuration. Plastic deformation occurs when the object does not return to its original configuration after the loads are removed. Energy is lost whenever an object experiences plastic deformation. Plastic deformation is permanent. Plasticity is a special form of material nonlinearity.

The current version allows for elastic material models that can be linear or nonlinear. Plasticity is reserved for a future version.

Equilibrium Equations

No material properties (constitutive equations) are used in the derivation of the equilibrium equations and as such, they are applicable to all materials. The equilibrium equation is given by:

The presented solid mechanics formulation is based on displacements as primary unknowns. This is a common approach [4, p.480], as the finite element solver will compute the displacements. The secondary unknowns such as strain and stress will be recovered from the displacements. While it is conceivable that equations are set up in such a manner that all unknowns are solved for, the resulting system of equations will become prohibitively large to solve in a reasonable time and with limited computer memory available.

The units of the solid mechanics model terms are force density in ![]() .

.

Body load

Body loads are forces that act on the entire volume of the object and arise from external force fields. These forces are also called volume forces and are specified as a force density in ![]() . Body loads are often also called body forces, but really they are a force per unit volume. Body loads can be specified with the parameter "BodyLoad" and are specified as a vector field. Gravity is an example of a constant body load; a position-dependent centrifugal force in rotating objects is another example.

. Body loads are often also called body forces, but really they are a force per unit volume. Body loads can be specified with the parameter "BodyLoad" and are specified as a vector field. Gravity is an example of a constant body load; a position-dependent centrifugal force in rotating objects is another example.

To model, for example, the self-weight of a body, one would have to specify the product of the mass density ![]()

![]() with the gravitational acceleration

with the gravitational acceleration ![]()

![]() such that the body load becomes

such that the body load becomes ![]()

![]() . Because this is a common case, an additional parameter "BodyLoadValue" can be specified. When "BodyLoadValue" is specified, the mass density

. Because this is a common case, an additional parameter "BodyLoadValue" can be specified. When "BodyLoadValue" is specified, the mass density ![]() is multiplied automatically and yields a body load.

is multiplied automatically and yields a body load.

Kinematic Equations

Kinematics is the mathematical formulation of the movement and deformation of objects. The formulations found will be independent of the forces causing these deformations. The displacement ![]() and strain

and strain ![]() are introduced and defined in the following sections.

are introduced and defined in the following sections.

Displacement versus deformation

The solution of the solid mechanics equations gives a set of three displacement functions, ![]() ,

, ![]() and

and ![]() , which are the displacements in the

, which are the displacements in the ![]() ,

, ![]() and

and ![]() directions, respectively. An arbitrary point

directions, respectively. An arbitrary point ![]() in an object originally at

in an object originally at ![]() is moved to

is moved to ![]() when the object is under load. The displacements are often collected in the displacement vector

when the object is under load. The displacements are often collected in the displacement vector ![]() .

.

If all points in a body experience the same displacement, there is no deformation. In other words, a body only deforms when there is nonuniform displacement. A rigid body motion of the object is represented by displacement with no deformation. A rotation or translation of a body is a rigid body motion.

A quantity related to the displacement is the displacement gradient, often denoted by ![]() :

:

For a rigid body translation, the displacement gradient is 0.

Deformation describes the relative movement of particles next to each other, while displacement describes absolute movement. Deformation captures changes in size and shape, while displacement does not.

Strain

Strain is a quantity that describes the amount of deformation or distortion within a body [2] and is a ratio and unitless.

A body that undergoes a rigid body motion like rotation or translation does not experience deformation; the name rigid body motion expresses this. A rigid body motion is pure displacement. Strain, however, is a consequence of a change in size or a change in shape. A good strain measure captures this requirement: strain should be zero for rigid body movements since it should only measure deformation.

Strain is not a physical quantity like temperature, and there are various strain measures. Almost all strain measures in use today [13, c. 4.1, p. 90] are constructed in such a way that they give more or less the same results when the deformation is small. For small deformations, it does not matter which strain measure is used.

A strain can be nonzero even when the displacement is zero. Consider a rod that is fixed at the left and pulled on the right in the positive ![]() direction. At the fixed end, the displacement will be zero, yet the strain is nonzero.

direction. At the fixed end, the displacement will be zero, yet the strain is nonzero.

The infinitesimal strain measure is also called the engineering strain measure or small strain measure.

A simple strain definition for a one-dimensional rod is given by

where ![]() is the length in

is the length in ![]() of an undeformed object,

of an undeformed object, ![]() is the length in

is the length in ![]() of the deformed object and

of the deformed object and ![]() is the change in length in

is the change in length in ![]() due to an applied load.

due to an applied load.

The above definition of strain is not what is actually used in the Wolfram Language but is useful for building an intuition. The derivation of the definition that is actually in use follows [4, p.475]. To describe the deformation of a body, a point in the original configuration and the same point in the final, deformed configuration are considered. An infinitesimal cube is considered to characterize the change in size and shape. The change in size is determined by the changes of length of the cube. The change in shape is determined by the change in angle from the original ![]() between the sides.

between the sides.

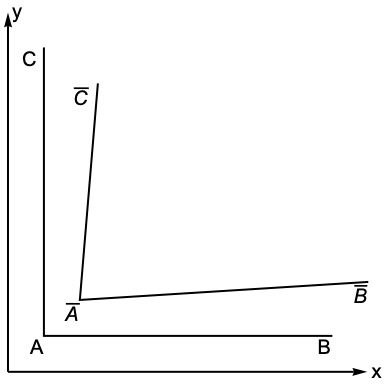

First, the changes in length are investigated. Consider a line segment ![]() parallel to the

parallel to the ![]() axis in the original configuration. A displacement moves this line to

axis in the original configuration. A displacement moves this line to ![]() in the final configuration.

in the final configuration.

Let's say point ![]() is at

is at ![]() . Then point

. Then point ![]() is at

is at ![]() since it is parallel to the

since it is parallel to the ![]() axis. The point

axis. The point ![]() is displaced by

is displaced by ![]() such that point

such that point ![]() is at

is at ![]() . The point

. The point ![]() is displaced by

is displaced by ![]() such that its position in the final configuration is

such that its position in the final configuration is ![]() . From these coordinates, the original and deformed length of segments

. From these coordinates, the original and deformed length of segments ![]() and

and ![]() can be computed as follows:

can be computed as follows:

Since ![]() is parallel to the

is parallel to the ![]() axis, the increments are functions of

axis, the increments are functions of ![]() only, it can be written

only, it can be written

Substituting back it leads to:

The normal strain in the ![]() direction is then defined as

direction is then defined as

So far this is exact. Now comes a crucial simplification that specifically leads to the infinitesimal strain measure. It is assumed that the displacements are small and that they are much smaller compared to 1. This means that

Thus the normal strain is approximated with

The same reasoning can be applied for the remaining normal strains in the ![]() and

and ![]() directions such that

directions such that

What remains to be done is to quantify the changes in the angles that are initially at ![]() . This will lead to an expression for the shear strains. The shear strains quantify the change in angle. Consider a line segment

. This will lead to an expression for the shear strains. The shear strains quantify the change in angle. Consider a line segment ![]()

![]() to line segment

to line segment ![]() in the original configuration. In the final configuration, these are displaced to

in the original configuration. In the final configuration, these are displaced to ![]() and

and ![]() , respectively.

, respectively.

The point ![]() originally at

originally at ![]() is displaced to

is displaced to ![]() . Since the assumption that displacements are small has already been made and only the change in angle is to be described, the change in length is ignored and the point

. Since the assumption that displacements are small has already been made and only the change in angle is to be described, the change in length is ignored and the point ![]() moves up by

moves up by ![]() relative to point

relative to point ![]() . Point

. Point ![]() moves to the right by

moves to the right by ![]() relative to

relative to ![]() . Again, changes in length are not considered when describing the change in angle. With the

. Again, changes in length are not considered when describing the change in angle. With the

Using this the shear stress is

Now, one could go ahead and group the components in a matrix like this:

This, however, would have some disadvantages. For one, the object above does not behave like a tensor and rules out other succinct ways of representing the object. Engineers measured shear strains long before tensors were invented. To remedy this situation, the tensorial shear strains ![]() are defined as

are defined as ![]() engineering shear strains

engineering shear strains ![]()

The strain tensor components are symmetric, and the complete infinitesimal strain tensor looks like this

This is what is called the infinitesimal strain measure. It is very important to realize that this strain definition can only be used if the deformation and rotations are small. If that is not the case, then other strain measures have to be used.

It is possible to switch off the usage of engineering strains by setting "EngineeringStrain"->False in the parameters pars. This may be of interest when comparing linear material laws with nonlinear material laws, where true strain is used. More information can be found in the reference page of SolidMechanicsStrain.

Using the tensorial strain, a tensor can be expressed as

where the vector ![]() is the displacement gradient.

is the displacement gradient.

The infinitesimal strain measure is the default strain measure that the Wolfram Language uses, as the default material model is a linear elastic material model. The choice was made as small deformations are the most common scenario that is modeled. Furthermore, the infinitesimal strain measure is linear and does not per se result in a system of nonlinear equations, which take longer to solve. The infinitesimal strain measure is useful for modeling small deformations of concrete, stiff plastics, metals, linear viscoelastic materials such as polymeric materials and porous media such as soils and clays at moderate loads; in fact, almost any material can be modeled with the infinitesimal strain measure if the load is not too high. The infinitesimal strain measure is inadequate for rubber materials, soft tissue or large deformations in general [13, c. 4.1, p. 95]. Those are dealt with in the Hyperelasticity monograph.

The infinitesimal strain measure has, however, limitations that one needs to be aware of. The infinitesimal strain does not produce a zero strain for a rigid body rotation. This is best illustrated by an example.

Note that the normal strains are not zero. The infinitesimal strain measure is only valid for small rotations. If rotations are large, other strain measures, such as the Green–Lagrange measure, are a better choice.

Unfortunately, it is not as simple as to just replace the infinitesimal strain with a, say, a Green–Lagrange strain, as the Green–Lagrange strain is not compatible with the Cauchy stress. This will be explained in much more detail in the section on hyperelasticity.

Before considering strain measure for large deformations, the concept of a deformation gradient is established. For small deformations, the difference between the object before and after the deformation is small compared to the size of the object and is neglected. In the case of large deformations, that is no longer the case, and the deformation needs to be accounted for.

The process begins by distinguishing between the undeformed object and the deformed object. In this section, the displacement vector ![]() will not be shown in bold to make the notation more consistent with the notation used in literature.

will not be shown in bold to make the notation more consistent with the notation used in literature.

The undeformed object is placed in a coordinate system with basis vectors ![]() . This domain is referred to as the reference configuration. For convection, capital letters are used to refer to entities from this domain. When this object undergoes deformation, every material point

. This domain is referred to as the reference configuration. For convection, capital letters are used to refer to entities from this domain. When this object undergoes deformation, every material point ![]() is displaced to a material point

is displaced to a material point ![]() on the deformed object. Lowercase letters denote all entities from the deformed domain. To keep things simple, both the object in the reference configuration and the object in the deformed configuration make use of the same coordinate system

on the deformed object. Lowercase letters denote all entities from the deformed domain. To keep things simple, both the object in the reference configuration and the object in the deformed configuration make use of the same coordinate system ![]() . The reference configuration is sometimes also called the material configuration or the initial configuration or the Lagrangian description, while the deformed configuration is sometimes called the spatial configuration or the current or final configuration or the Eulerian description.

. The reference configuration is sometimes also called the material configuration or the initial configuration or the Lagrangian description, while the deformed configuration is sometimes called the spatial configuration or the current or final configuration or the Eulerian description.

The deformation function ![]() maps

maps ![]() to

to ![]() :

:

The infinitesimal line segment ![]() :

:

where ![]() is the identity matrix and

is the identity matrix and ![]() is the deformation gradient with components

is the deformation gradient with components

where ![]() is the Kronecker delta. In matrix form,

is the Kronecker delta. In matrix form, ![]() can be written as

can be written as

The deformation gradient ![]() can also be expressed in terms of the spatial and material coordinates. Where:

can also be expressed in terms of the spatial and material coordinates. Where:

The deformation gradient matrix ![]() is the Jacobian matrix of the deformation map

is the Jacobian matrix of the deformation map ![]() . The deformation gradient tensor allows the relative position of two neighboring particles in the deformed configuration to be described in terms of their relative particle's position in the reference configuration [17, p. 81].

. The deformation gradient tensor allows the relative position of two neighboring particles in the deformed configuration to be described in terms of their relative particle's position in the reference configuration [17, p. 81].

The deformation gradient is at the heart of nonlinear solid mechanics.

The Green–Lagrange strain measure is a nonlinear strain measure that does not suffer from the small displacement and rotation limitations the infinitesimal strain measure is limited by. Conceptually, the Green–Lagrange strain measure models

where ![]() is the length in

is the length in ![]() of an undeformed object and

of an undeformed object and ![]() is the length in

is the length in ![]() of the deformed object.

of the deformed object.

To show that the Green–Lagrange strain measure does not suffer from the small deformation limit, the same example is considered as in the infinitesimal strain section but makes use of the Green–Lagrange strain measure.

In the case of the Green–Lagrange strain, the normal and shear strains are zero, as expected for rigid body motions.

The Green–Lagrange strain measure is implemented by computing the deformation gradient ![]()

where ![]() is the identity matrix. The Green–Lagrange tensorial strain

is the identity matrix. The Green–Lagrange tensorial strain ![]() is given by:

is given by:

The Green–Lagrange strain measure is a material strain tensor that describes the strain in the reference configuration. This is in contrast to, for example, the Euler–Almansi strain measure that describes the strain in the deformed configuration.

For completeness, the Euler–Almansi strain ![]() is also given. The Euler–Almansi strain measure is a spatial strain tensor that describes the strain in the deformed configuration. Conceptually, the Euler–Almansi strain models:

is also given. The Euler–Almansi strain measure is a spatial strain tensor that describes the strain in the deformed configuration. Conceptually, the Euler–Almansi strain models:

where ![]() is the length in

is the length in ![]() of an undeformed object and

of an undeformed object and ![]() is the length in

is the length in ![]() of the deformed object.

of the deformed object.

The Euler–Almansi tensorial strain is given by:

The strain measure actually used can be inspected.

Poisson's ratio

Poisson's ratio ![]() gives the relation between the lateral contraction and longitudinal expansion when a body is pulled in the longitudinal direction

gives the relation between the lateral contraction and longitudinal expansion when a body is pulled in the longitudinal direction

An isotropic material is a material that behaves the same in all directions. It is assumed that the ![]() direction is the longitudinal direction and the

direction is the longitudinal direction and the ![]() and

and ![]() directions are the lateral directions. In the elastic region:

directions are the lateral directions. In the elastic region:

because the material is isotropic ![]() and the relation of

and the relation of ![]() to

to ![]() and

and ![]() is Poisson's ratio:

is Poisson's ratio:

For an isotropic linear elastic material, Poisson's ratio ![]() is a value between

is a value between ![]() . For most metals, Poisson's ratio is about 1/3. Many materials have a Poisson ratio of 0.2–0.3. On the extreme ends, cork, for example has a Poisson ratio of 0. Rubber, for example, can have a Poisson ratio of close to

. For most metals, Poisson's ratio is about 1/3. Many materials have a Poisson ratio of 0.2–0.3. On the extreme ends, cork, for example has a Poisson ratio of 0. Rubber, for example, can have a Poisson ratio of close to ![]() . Poisson ratio values of

. Poisson ratio values of ![]() mean that the material is incompressible and pose a problem for numerical simulation. Artificial material, such as auxetic material, can have a negative Poisson ratio. If an auxetic material is stretched in one direction, it becomes thicker in the other direction.

mean that the material is incompressible and pose a problem for numerical simulation. Artificial material, such as auxetic material, can have a negative Poisson ratio. If an auxetic material is stretched in one direction, it becomes thicker in the other direction.

Constitutive Equations

The constitutive equations relate the equilibrium equations with the kinematic equations via the material model. Before discussing these, the concept of stress is introduced.

Stress

Stress is the consequence of what happens in the material when it is deformed. Stress is a quantity that describes the distribution of internal forced within a body [2] and is measured in ![]() or

or ![]()

where ![]() is the force in

is the force in ![]() and

and ![]() is the initial area in

is the initial area in ![]() the force acts on.

the force acts on.

Finding the stresses in an object is an important task, as it allows when the object will fail to be predicted. Say a material can withstand a maximum stress of ![]() . A material will fail if

. A material will fail if ![]() . The maximum force that can be applied before the material fails is

. The maximum force that can be applied before the material fails is

For more information, see the section Failure Theory.

Stress-strain relation

The relation between stress and strain is a material property and can be visualized in a stress-strain diagram. The data for these diagrams comes from tensile tests. For these tests, a material specimen is clamped into a machine that has two clamps and pulls the specimen apart. The force applied and the strain produced are recorded until a fracture occurs.

At a minimum, the data needs to contain the load applied by the machine and the measured strain.

For the stress computation, the diameter of the specimen is needed.

Typically, the last data point is a recording of the rupture of the material and needs to be removed.

The above material data is from cold rolled steel and as such is a ductile material. A more brittle material, for example aluminum, would have a much less distinct flat top part.

The areas under the curves correspond to the absorbed energy.

The stress-strain curve relates the measured strain to the force and hence stress applied. An archetypical stress-strain curve has several sections worth discussing. The following illustrates an exaggerated stress-strain curve for a ductile material. Several points of interest have been marked. Especially, the points A, B and C may be very close together, or the connection between A and C may be a straight line. What is happening physically at these points of the stress-strain curve is that the material slips along internal crystal boundaries. This happens very fast and is hard to detect.

The following points of interest are marked:

- A: The proportionality limit. Up until this point, the stress-strain curve is linear. Hooke's law applies here.

- B: The elastic limit. This point is beyond the linear stress-strain relation and marks the end of the nonlinear elastic region. This means that a load that is applied up until this point will not cause a permanent deformation. Up until this point, the material is still fully elastic and after removal of the load, the material will return to its original form. Beyond this point, a permanent plastic deformation is observed.

- C: The yield point. Beyond this point, the strain will increase rapidly. If the yield point of a material is unknown, it is typically estimated with the 0.2% offset method. For this, a line parallel to the linear part of the curve is drawn that starts at strain of 0.002 (or 0.2%). The point where that parallel line intersects the stress-strain curve is taken as the yield point. Some industries may have a lower offset value. The elastic limit and the yield point are typically very close.

- D: The ultimate strength is the maximum stress value of a material. The ultimate strength is also called the tensile strength. Beyond this point, the material will exhibit a phenomenon called necking. Here the cross-sectional area of the test specimen will start to become thinner, much like the neck of a droplet before breaking off.

The initial section is the linear section. Here the relation between stress and strain is linear and known as Hooke's law. A load applied in this region is fully reversible. This region is also called the elastic region. In this region:

where ![]() is Young's modulus and a material property. Young's modulus is also called modulus of elasticity. Young's modulus has the same units as stress

is Young's modulus and a material property. Young's modulus is also called modulus of elasticity. Young's modulus has the same units as stress ![]() . The material property Young's modulus is measured with a uniaxial tension test.

. The material property Young's modulus is measured with a uniaxial tension test.

More in-depth information and material data for the stress-strain relation can be found in [14].

True stress and strain

Stress-strain curves are obtained from tensile tests. In these tests, a specimen is pulled apart by a force, which applies a stress and the strain is recorded. During the test, the specimen will deform, and as a consequence, the cross-sectional area will change. The cross-sectional area, however, enters the equation for the stress as:

It is difficult to measure the instantaneous cross-sectional area during testing, so only the initial form of the specimen is recorded. The true stress and strain, however, take the change of form into account.

Consider an undeformed cuboid with length ![]() and area

and area ![]() shown in here as a 2D cross section. The specimen is subject to forces

shown in here as a 2D cross section. The specimen is subject to forces ![]() under which it deforms and now has length

under which it deforms and now has length ![]() and area

and area ![]() .

.

The engineering stress ![]() is given as:

is given as:

The difference comes during measurement of stresses in a test specimen. Typically, only the original area of the specimen is considered. The same holds true for the strains. The true strain is given as

The engineering strain is given as

Next, the volume of the specimen is assumed to stay constant. This assumption is valid in the elastic region because volume changes in the elastic region will be small. The assumption is also valid in the first part of the plastic region because materials are considered incompressible during this part of plastic deformation. The assumption, however, is no longer valid in the second part of the plastic region after the process of necking has started.

Under the constant volume assumption, the following conversions can be established:

Also note that for small strain values, inside the elastic region the difference between the true and engineering stresses and strains is small compared to the difference in the plastic region. In cases where there is significant plastic deformation, the true stress-strain curve should be used.

Using the data from the above section Stress-Strain relation, the engineering stress and strain are converted into true stress and strain.

The Wolfram Language uses engineering strain.

Linear Elastic Material Models

The constitutive equation is also called the material model. The constitutive equation describes how stress and strain are related. In the linear case, stress ![]() and strain

and strain ![]() are related by a generalization of Hooke's law through the elasticity matrix

are related by a generalization of Hooke's law through the elasticity matrix ![]() :

:

Sometimes the elasticity matrix is also called the constitutive matrix or the material stiffness matrix.

In the most general case, the elasticity matrix ![]() of the linear elastic constitutive equation is given as:

of the linear elastic constitutive equation is given as:

The ![]() are the shear stresses. These are used to indicate that the engineering shear strains

are the shear stresses. These are used to indicate that the engineering shear strains ![]() are considered.

are considered.

The number of the elastic constants ![]() can be reduced. This simplification is achieved by making several assumptions [4, p.478]. It is almost universally assumed that the elasticity matrix is symmetric. This assumption reduces the 36 elastic constants to 21.

can be reduced. This simplification is achieved by making several assumptions [4, p.478]. It is almost universally assumed that the elasticity matrix is symmetric. This assumption reduces the 36 elastic constants to 21.

Further reductions are possible if the material exhibits symmetries about some planes. The exact form of the elasticity matrix ![]() depends on these symmetries. Typically, a distinction is made between isotropic and anisotropic materials. In an isotropic material, all material properties are the same in all directions. Most metals are isotropic materials. All materials that are not isotropic are called anisotropic. In the most general case, anisotropic means that a material behaves differently in all possible directions.

depends on these symmetries. Typically, a distinction is made between isotropic and anisotropic materials. In an isotropic material, all material properties are the same in all directions. Most metals are isotropic materials. All materials that are not isotropic are called anisotropic. In the most general case, anisotropic means that a material behaves differently in all possible directions.

Because the general anisotropic case is indeed very general, special named subcases exist. For example, in an orthotropic material, the material properties are different in each of the object's axis directions. Wood is considered an orthotropic material, where the material properties depend on the direction of the wood grain.

Generally speaking, anisotropic materials are typically compound material or biological tissue where the material properties vary in some or all directions. Fiber-reinforced materials where the weave affects the material properties in all directions are also considered anisotropic.

If the orientation of the geometric model does not match the orientation of the material properties, then an orientation matrix needs to be specified. This procedure is outlined in the section on material orientation.

A linear elastic material model is good for the vast majority of engineering design calculations, where components cannot exceed yield [11, c.1.1.5].

The subsequent sections will introduce these linear material models.

In the case where both the constitutive equation and the kinematic equation are linear, the equations can be simplified into a form like:

where ![]() and

and ![]() transforms the elasticity matrix

transforms the elasticity matrix ![]() into its full tensor form

into its full tensor form ![]() . The full tensor form is what is seen from the output of SolidMechanicsPDEComponent.

. The full tensor form is what is seen from the output of SolidMechanicsPDEComponent.

This is explained in more detail in the section The Output of SolidMechanicsPDEComponent.

Isotropic linear elastic materials

The isotropic linear elastic material model is the default material model used in the Wolfram Language. A material is described as isotropic if it behaves the same in all directions. In other words, its material properties are direction independent. An isotropic linear elastic material model is good for polycrystalline metals, ceramics, glass and polymers undergoing small deformations and low loads [11, c.1].

The elasticity matrix for an isotropic material is given by:

The Young's modulus ![]() and Poisson's ratio

and Poisson's ratio ![]() are the only elastic coefficients needed to specify the elasticity matrix.

are the only elastic coefficients needed to specify the elasticity matrix.

This is the linear variant of the term ![]() .

.

For the linear elastic isotropic case, the commonly used Young modulus and Poisson ratio can be expressed in terms other than elastic moduli.

Currently, the functionality that the various moduli can be expressed in terms of each other is available in 3D only.

Any elastic modulus can be expressed in terms of any other two moduli. Hence it is possible to use any of the common moduli, and SolidMechanicsPDEComponent will find the moduli it needs for its operation.

Orthotropic linear elastic materials

Orthotropic material have different properties in the three dimensions. Wood is an example that can be modeled as an orthotropic material. Consider a wood log. The wood then is most stiff along the grain, somewhat stiff in the circumferential direction and least stiff in the radial direction.

The general form for orthotropic materials is given as:

To keep things simple, the coefficients of elasticity matrix ![]() are typically not given explicitly but are defined through the compliance matrix

are typically not given explicitly but are defined through the compliance matrix ![]() . Here it reads

. Here it reads ![]() :

:

Note that the elasticity matrix ![]() can be found by inverting the compliance matrix

can be found by inverting the compliance matrix ![]() such that

such that ![]() .

.

This is the linear variant of the term ![]() .

.

Transversely isotropic linear elastic materials

Transverse isotropy is a special type of orthotropy. Orthotropic materials are symmetric with respect to three orthogonal planes. Transversely isotropic materials are symmetric with respect to one orthogonal plane.

Transverse isotropic materials have the same physical properties in an infinitesimal thin layer. Sedimentary rocks are an example. These rocks are made up from various layers, say in the ![]() and

and ![]() directions. Material properties, like stiffness, are the same in the

directions. Material properties, like stiffness, are the same in the ![]() and

and ![]() directions. In the direction of the layers, the

directions. In the direction of the layers, the ![]() direction, however, the physical properties change and the material is orthotropic with respect to that direction.

direction, however, the physical properties change and the material is orthotropic with respect to that direction.

In other words, transversely isotropic materials have one axis of symmetry around which the material is symmetric. This means that after rotation of the material about the axis, it behaves like an isotropic material in the plane to which the axis is normal. Transversely isotropic material is a material class that sits between isotropic and orthotropic material.

Another example of a transverse isotropic object would be a biological membrane. In this case, the material properties of the membrane will be the same in the plane of the membrane but different from those in the perpendicular direction.

The material properties of sedimentary rocks are the same in the ![]() and

and ![]() directions, which form the plane of isotropy. In the

directions, which form the plane of isotropy. In the ![]() direction, the material properties differ.

direction, the material properties differ.

A second type of materials falling into the category of transversely isotropic materials are materials that are reinforced by one family of fibers running in the same direction. In this case, the fibers take the role of the axis around which the material is symmetric. Fiber-reinforced materials are usually much stiffer in the direction of the fibers than in the transverse direction.

A fiber-reinforced composite with a single type of a fiber embedded in a material matrix.

A difference between fiber-reinforced materials and sedimentary rocks is the structure of their cross section. A sedimentary rock is homogeneous in the plane of isotropy, while a fiber-reinforced material is not.