WOLFRAM SYSTEM MODELER

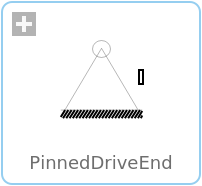

PinnedDriveEndComponent that can act as a pinned drive end to a beam, containing different options |

|

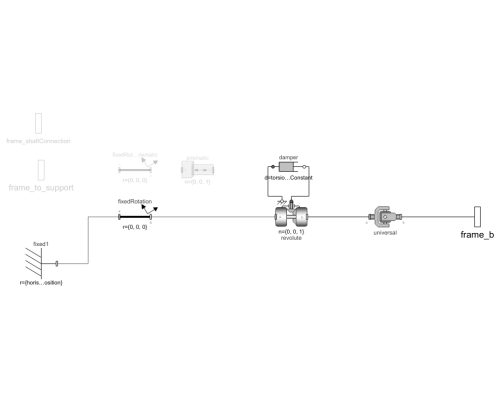

Diagram

Wolfram Language

SystemModel["RotatingMachinery.Supports.PinnedDriveEnd"]

Information

Hinge Support - Pinned Drive End

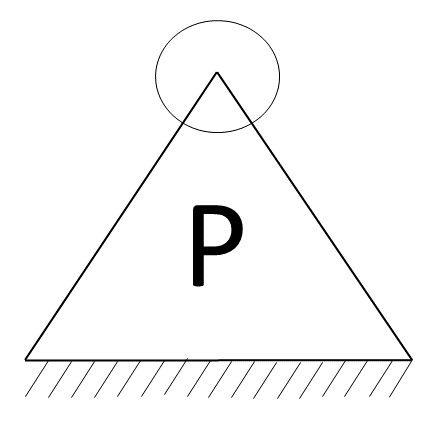

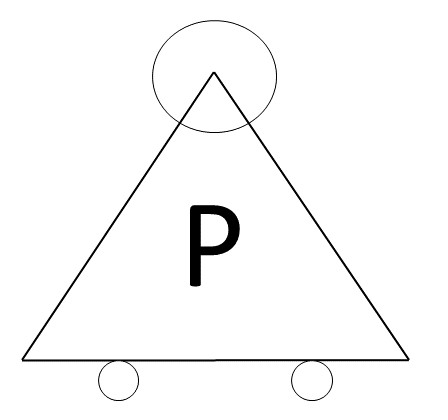

This class contains components that act as support to a beam. Depending on the settings of the parameters, the support will act as pinned (hinged) or pinned-free (roller) support. The default setting is a pinned support with a locked position in the axial direction (z axis).

Figure 1: Pinned supports [1].

Preceding are two images showing the difference in setting the axialFixed = true (left) or false (right).

This component acts as the drive end because the condition between the initial revolute angle (revolute.phi) is set to fixed = true. In its counter-class, PinnedNonDriveEnd, the initial revolute angle is set to fixed = false. This means that the drive end will set the initial condition for the components connected to it, while the non-drive end will follow.

All models will need one or more supports. In this model, a pinned support is connected to a beam and can function as either a hinged or roller support depending on the parameter settings shown below.

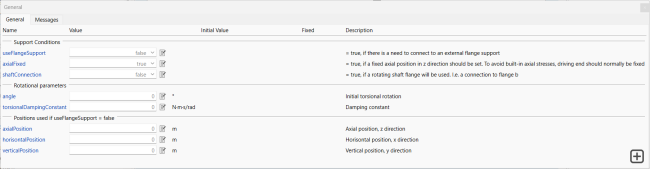

Figure 2: Support parameters tab

By default, axialFixed is set to true, meaning that it will act as a pinned support with a fixed axial position. Note that it does not restrict rotational displacements. There are two other types of supports: fixed and flexible.

Parameters:

- useFlangeSupport = Set to true if the support should be connected to an external flange

- axialFixed = Set to true if the support should act as only a pinned support; set to false if the support should act as a pinned-free support. If set to true, the following parameters will be relevant:

- AxialPosition = Defines the axial position (z axis) of the fixed point the beam is connected to

- HorizontalPosition = Defines the horizontal position (x axis) of the fixed point the beam is connected to

- VerticalPosition = Defines the vertical position (y axis) of the fixed point the beam is connected to

- shaftConnection = Set to true if a rotating shaft flange should be connected to flange b

References

[1] Schmid, S. R., B. J. Hamrock and Bo. O. Jacobson. Fundamentals of Machine Elements. CRC Press, 2013.

Parameters (8)

| useFlangeSupport |

Value: false Type: Boolean Description: = true, if there is a need to connect to an external flange support |

|---|---|

| axialFixed |

Value: true Type: Boolean Description: = true, if a fixed axial position in z direction should be set. To avoid built-in axial stresses, driving end should normally be fixed |

| shaftConnection |

Value: false Type: Boolean Description: = true, if a rotating shaft flange will be used. I.e. a connection to flange b |

| angle |

Value: 0 Type: Angle_deg (°) Description: Initial torsional rotation |

| torsionalDampingConstant |

Value: 0 Type: RotationalDampingConstant (N⋅m⋅s/rad) Description: Damping constant |

| axialPosition |

Value: 0 Type: Length (m) Description: Axial position, z direction |

| horisontalPosition |

Value: 0 Type: Length (m) Description: Horisontal position, x direction |

| verticalPosition |

Value: 0 Type: Length (m) Description: Vertical position, y direction |

Connectors (3)

| frame_b |

Type: Frame_b Description: Coordinate system fixed to the component with one cut-force and cut-torque (non-filled rectangular icon) |

|

|---|---|---|

| frame_to_support |

Type: Frame_b Description: Coordinate system fixed to the component with one cut-force and cut-torque (non-filled rectangular icon) |

|

| frame_shaftConnection |

Type: Frame_b Description: Coordinate system fixed to the component with one cut-force and cut-torque (non-filled rectangular icon) |

Components (7)

| revolute |

Type: Revolute Description: Revolute joint (1 rotational degree-of-freedom, 2 potential states, optional axis flange) |

|

|---|---|---|

| universal |

Type: Universal Description: Universal joint (2 degrees-of-freedom, 4 potential states) |

|

| fixedRotation |

Type: FixedRotation Description: Fixed translation followed by a fixed rotation of frame_b with respect to frame_a |

|

| damper |

Type: Damper Description: Linear 1D rotational damper |

|

| fixed1 |

Type: Fixed Description: Frame fixed in the world frame at a given position |

|

| prismatic |

Type: Prismatic Description: Prismatic joint (1 translational degree-of-freedom, 2 potential states, optional axis flange) |

|

| fixedRotationPrismatic |

Type: FixedRotation Description: Fixed translation followed by a fixed rotation of frame_b with respect to frame_a |

Used in Examples (9)

|

RotatingMachinery.Examples.BearingAnalysis Two roller bearings on flexible supports |

|

|

RotatingMachinery.Examples.BearingAnalysis Frequency analysis of a bearing defect on a simple shaft mounted on a structure |

|

|

RotatingMachinery.Examples.Gears.SpurGears Building a two-wheeled gear train on shafts |

|

|

RotatingMachinery.Examples.Gears.SpurGears Construction of triple gearbox on three shafts |

|

|

RotatingMachinery.Examples.JeffcottRotorDamping Determine shaft damping |

|

|

RotatingMachinery.Examples.JeffcottRotorDamping A basic Jeffcott rotor with internal and external damping |

|

|

RotatingMachinery.Examples.RotorBalancing An unbalanced rotor stabilized by balancing planes |

|

|

RotatingMachinery.Examples.Shafts Inspection of an axle's vibrations |

|

|

RotatingMachinery.Examples.Shafts Inspection of a car axle deflection on tires |

Used in Components (1)

|

RotatingMachinery.Gears.PlanetaryGears This component is a three-shaft gearbox and is a part of the wind turbine gearbox |