WOLFRAM SYSTEM MODELER

ClampedDriveEndComponent that can act as a clamped drive end to a beam, containing different options |

|

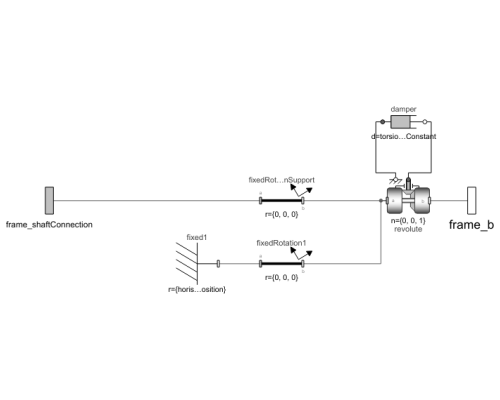

Diagram

Wolfram Language

SystemModel["RotatingMachinery.Supports.ClampedDriveEnd"]

Information

Clamped Drive End Support

This component acts as support to a beam/shaft. Depending on the settings of the parameters, the support will act as a clamped support with a built-in fixed point or a clamped support that connects to another frame (activated by setting useFlangeSupport to true). The default setting is a clamped support with a built-in fixed point.

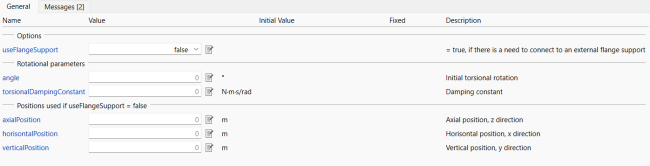

Figure 1: Clamped support parameters tab.

Figure 1: Clamped support parameters tab.

A clamped support only enables rotation around the beam axis (z axis). If a translational movement in the beam axis should be allowed, use the useFlangeSupport and connect to a prismatic joint that allows for that movement.

References

[1] Schmid, S. R., B. J. Hamrock and Bo. O. Jacobson. Fundamentals of Machine Elements. CRC Press, 2013.

Parameters (6)

| useFlangeSupport |

Value: Type: Boolean Description: = true, if there is a need to connect to an external flange support |

|---|---|

| angle |

Value: 0 Type: Angle_deg (°) Description: Initial torsional rotation |

| torsionalDampingConstant |

Value: 0 Type: RotationalDampingConstant (N⋅m⋅s/rad) Description: Damping constant |

| axialPosition |

Value: 0 Type: Length (m) Description: Axial position, z direction |

| horisontalPosition |

Value: 0 Type: Length (m) Description: Horisontal position, x direction |

| verticalPosition |

Value: 0 Type: Length (m) Description: Vertical position, y direction |

Connectors (2)

Components (5)

| fixedRotation1 |

Type: FixedRotation Description: Fixed translation followed by a fixed rotation of frame_b with respect to frame_a |

|

|---|---|---|

| fixed1 |

Type: Fixed Description: Frame fixed in the world frame at a given position |

|

| fixedRotationSupport |

Type: FixedRotation Description: Fixed translation followed by a fixed rotation of frame_b with respect to frame_a |

|

| revolute |

Type: Revolute Description: Revolute joint (1 rotational degree-of-freedom, 2 potential states, optional axis flange) |

|

| damper |

Type: Damper Description: Linear 1D rotational damper |

Used in Examples (10)

|

RotatingMachinery.Examples.StabilityAnalysis Finding whirling frequencies of a rotating shaft: Part I |

|

|

RotatingMachinery.Examples.StabilityAnalysis Finding whirling frequencies of a rotating shaft: Part II |

|

|

RotatingMachinery.Examples.Gears.PlanetaryGears A basic planetary gear application; WindTurbine Part I |

|

|

RotatingMachinery.Examples.Gears.PlanetaryGears Building a three-shaft gearbox; WindTurbine Part II |

|

|

RotatingMachinery.Examples.Gears.PlanetaryGears Assembly of a planetary gear and a three-shafted gearbox; Part I and Part II |

|

|

RotatingMachinery.Examples.ContactAnalysis Study of contact forces between a disk and a housing |

|

|

RotatingMachinery.Examples.ContactAnalysis Study of a running up clamped free rotor |

|

|

RotatingMachinery.Examples.ContactAnalysis Inspection of deflection of a free rotor without clearance |

|

|

RotatingMachinery.Examples.ContactAnalysis Calculation of deflection for a rotor with a surrounding and a clearance |

|

|

RotatingMachinery.Examples.ContactAnalysis Application of a running down rotor deflection with a clearance |